Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

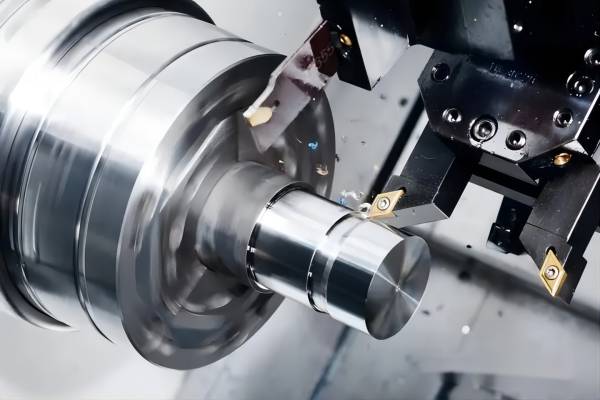

As we said a lot about CNC machining earlier, the history of CNC machining dates back to the 1870s, but the manufacturing process is still evolving. Some of the current trends driving CNC machining into the future include:

Internet of Things (IoT)

The Internet of Things has manufacturing applications such as remote monitoring, overall machine shop optimization and predictive maintenance.

This means more CNC machines can run more efficiently with fewer operators, reducing overhead costs and passing savings on to customers.

Intelligent devices can also be used in manufacturing to optimize material use through computer-integrated manufacturing (CIM).

Machines can process materials more efficiently while improving part quality by monitoring temperature and other variables. This allows for leaner production runs while reducing energy costs and associated CO2 emissions.

Another application is the use of smart devices in CNC machine shops for low-volume manufacturing. These devices can monitor operations and provide feedback, helping manufacturers streamline processes and enabling them to take on more work.

Rapid Prototyping and Digital Manufacturing

As we've already mentioned, CNC machining is an excellent choice for the manufacturing portion of the rapid prototyping process.

However, with the rise of accessible CAD programs such as Tinkercad, Trimble Sketchup, and Autodesk 123D (formerly known as Kinect), more and more businesses and individuals are able to take advantage of CNC machining without having to purchase their own CNC machines.

With these programs, it's becoming easier and easier to generate CAD designs for physical parts that can then be sent to others to manufacture.

This means that smaller startups no longer need to worry about minimum order quantities and overseas manufacturing. They can simply generate a CAD model of their design and have it manufactured by a local CNC machine shop using a digital manufacturing platform such as Jiga.

This rapid, local and digital design and prototyping process means that more products are coming to market than ever before.

November 04, 2024

November 03, 2024

August 27, 2021

August 26, 2021

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

Application Performance Advantages of MC nylon MC nylon is a new type of engineering plastics, due to its outstanding comprehensive performance, so that its status in engineering plastics is rapidly...

Types of nylon: 1. Nylon - 6 (PA6) Nylon -6, also known as polyamide -6, that is, polycaprolactam. Translucent or opaque opalescent resin. 2. Nylon - 66 (PA66) Nylon-66, also known as polyamide-66,...

What are the common machining methods used for PTFE parts processing? PTFE parts processing commonly used machining methods are: Molding Molding is suitable for processing simple parts directly once...

Email to this supplier

November 04, 2024

November 03, 2024

August 27, 2021

August 26, 2021

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.