Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

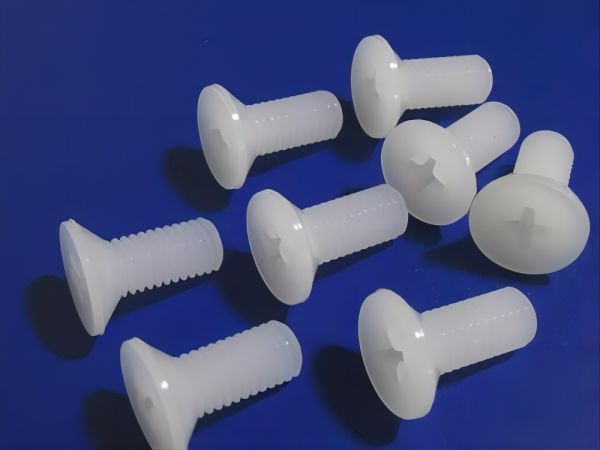

What is the difference between PVDF and PEEK screws?

PEEK (Polyetheretherketone) screw materials have extremely high continuous use temperatures (about 260 degrees), and also have high bending stiffness and strength, as well as unique high compressive strength and fatigue resistance. In addition, it has outstanding high temperature resistance, non-deformation performance and organic chemical stability. When the temperature reaches 260 degrees, the material has good electrical polarization properties and can resist direct kinetic X-ray radiation. PEEK has comprehensive properties, good mechanical performance, high temperature resistance, and excellent solvent resistance, making it a practical high-grade plastic.

Features: high impact toughness, stiffness and strength, high temperature resistance, acid resistance and hydrolysis resistance, wear resistance and friction performance, etc. PEEK is widely used in aerospace, diagnosis and treatment, machinery and equipment, vehicles and food manufacturing and other fields.

PVDF (polyylidene fluorobutadiene) has higher bending stiffness and pressure resistance than similar PTFE, but is less smooth and has less electrical insulation properties. It has high toughness and high wear resistance under ultra-low temperature conditions. Its working temperature ranges from -30 degrees to 150 degrees. PVDF can withstand fluoride, bromide and their kinetic energy X-rays for a long time.

Features: high air working temperature (can work continuously at 150 degrees), excellent resistance to chemical corrosion and hydrolysis, outstanding UV resistance and weather resistance. It has high impact toughness, good stiffness and good stress relaxation resistance. Excellent rolling properties and wear resistance. Original low flammability and good insulation performance.

However, in terms of use temperature and mechanical performance, PEEK is better than PVDF.

November 15, 2024

November 14, 2024

August 27, 2021

August 26, 2021

November 03, 2024

PVDF Application Areas Different models of PVDF products are suitable for different application scenarios. According to application fields, PVDF can be divided into conventional grade products and...

PEEK has been used very successfully in the analytical testing instrument industry, and piping and fittings made from PEEK material can be very convenient. Typical product forms are: PEEK Hand tight...

What is PVDF loop flange ? PVDF looper flange (Flange), also known as flange flange or flange. Flanges are parts that are connected to each other between shafts and are used for connection between...

What are the obvious differences between PVDF pipes and PP pipes? PVDF pipe is a translucent material pipe with high mechanical strength, good radiation resistance and excellent chemical stability....

Email to this supplier

November 15, 2024

November 14, 2024

August 27, 2021

August 26, 2021

November 03, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.