PEEK Tube round bar stick plastic Rod

Get Latest Price| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Min. Order: | 1 Kilogram |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,HongKong |

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Min. Order: | 1 Kilogram |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,HongKong |

Model No.: HONYPLAS-PEEK rod

Brand: HONYPLAS

| Selling Units | : | Kilogram |

| Package Type | : | Export carton pallet |

The file is encrypted. Please fill in the following information to continue accessing it

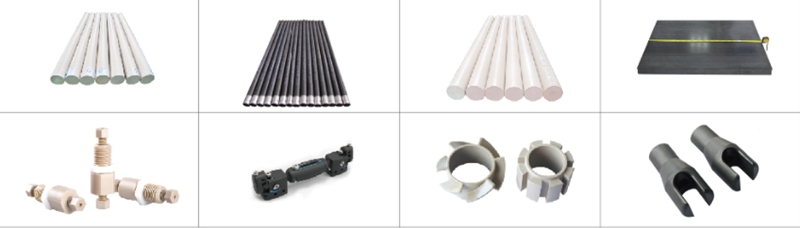

HONYPLAS®PEEK rod (abbreviation for PolyEtherEtherKetone) is polyether ether ketone rod, is a kind of semi-finished product extruded from PEEK raw materials, which has the characteristics of high temperature resistance, high wear resistance, high tensile strength, and good flame retardancy. PEEK rods can be used to process various specifications of PEEK parts, and can manufacture high-demand mechanical parts, such as gears, bearings, valve seats, sealing rings, pump wear rings, gaskets, etc. Parts processed with PEEK rods are widely used in key connectors in aerospace, medical, semiconductor, pharmaceutical and food processing industries.

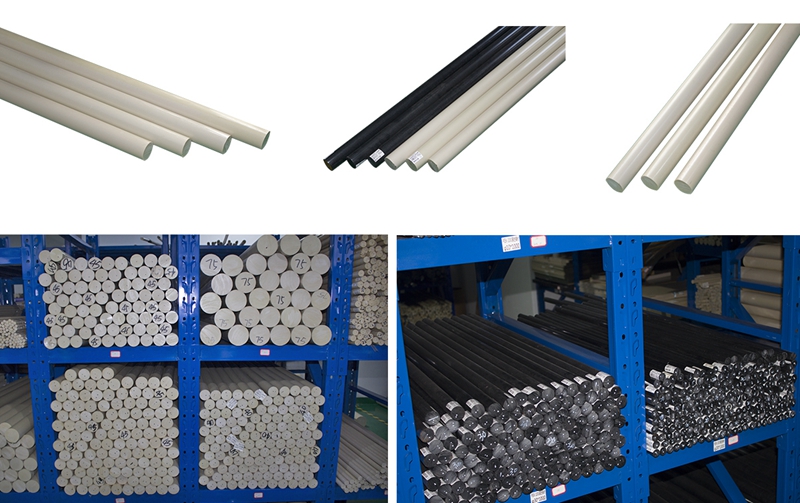

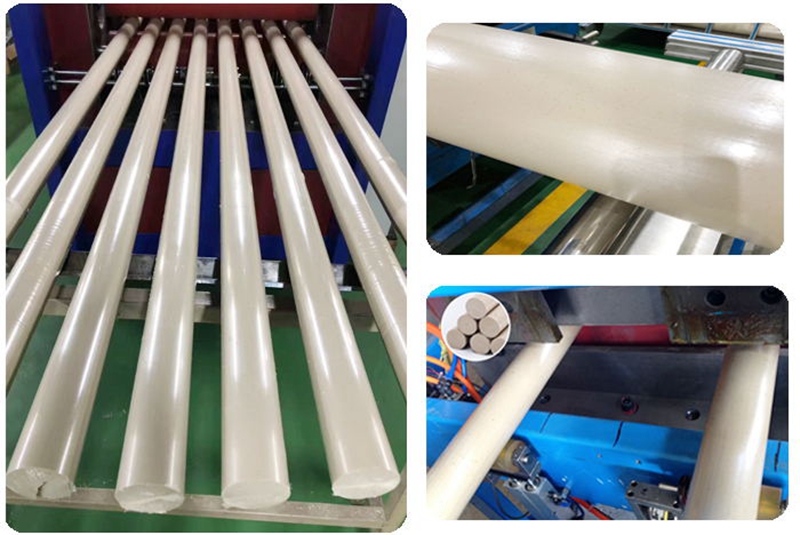

HONYPLAS PEEK rod with continuous extrusion process is more suitable for small batch and large size products to be produced by machining. The diameter range provided is 5-250mm, the length is 1000mm, 3000mm, and it can also be cut according to customers' non-standard Size, HONY has nearly a hundred kinds of extruding dies with diameter specifications, which are stocked all year round.

HONYPLAS®PEEK rod has a smooth surface, no black spots, good toughness, easy processing, favorable price, and excellent performance. After a third-party quality inspection, it can completely replace TECAPEEK

HONYPLAS®PEEK is manufactured may use Victrex® PEEK 450G or ZYPEEK® 550G polymer. Strong, stiff plastic with outstanding chemical resistance; performs over a wide range of temps

PEEK PERFORMANCE

Properties of PEEK plastic include high temperature performance, excellent wear properties, superior chemical resistance and outstanding toughness and strength. It also has excellent deformation under load characteristics, a high flexural modulus, and exhibits low smoke and toxic gas emissions when exposed to a flame.

MACHINING PEEK

In its solid state, PEEK is readily machinable by CNC milling machines and is commonly used to produce high-quality plastic parts that are thermostable and both electrically and thermally insulating. PEEK is often considered a superior high-end engineering plastic, in the same category as Delrin, PTFE or nylon.

FDA APPROVAL

Unfilled PEEK has been approved by the FDA for food contact applications.

PEEK COLORS

PEEK is naturally a very light brown or tan color as displayed in our images below, and is also available in black. Since it is an engineering plastic, color variations may occur between batches.

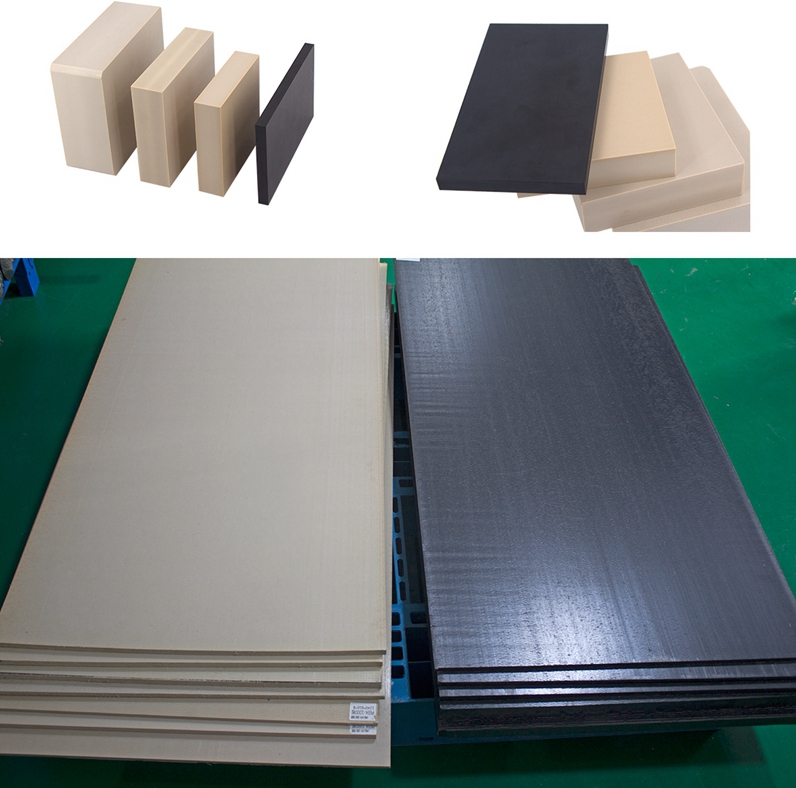

PEEK plastic sheets are the perfect choice for any high-tolerance, high-heat, chemical resistant plastic requirements, no matter how large or small!

The excellent performance of PEEK material is mainly manifested in the following aspects:

1. High temperature resistance

PEEK has a high glass transition temperature and melting point (334°C), which is one of the reasons why it can be reliably used in applications requiring heat resistance. Its load thermal deformation temperature is as high as 316℃, and its continuous use temperature is 260℃.

2. Mechanical characteristics

PEEK is a plastic with a balance between toughness and rigidity. In particular, its excellent fatigue resistance to alternating stress is the most outstanding among all plastics, comparable to alloy materials.

3. Self-lubricating

PEEK has outstanding sliding properties among all plastics, and is suitable for applications that strictly require low friction coefficient and abrasion resistance. In particular, the self-lubricating performance of PEEK modified with carbon fiber and graphite in a certain proportion is better.

4. Chemical resistance (corrosion resistance)

PEEK has excellent chemical resistance. Among ordinary chemicals, only concentrated sulfuric acid can dissolve or destroy it. Its corrosion resistance is similar to that of nickel steel.

5. Flame retardancy

PEEK is a very stable polymer. Samples with a thickness of 1.45mm can reach the highest flame retardant standards without adding any flame retardants.

6. Peel resistance

PEEK has good peel resistance, so it can be made into thin-covered wires or magnet wires, and can be used under harsh conditions.

7. Fatigue resistance

PEEK has the best fatigue resistance of all resins.

HONYPLAS®PEEK Product grade:

1.HONYPLAS®PEEK Virgin : Brown-gray, made of pure polyether ether ketone resin as raw material, has good toughness and impact resistance among all PEEK grades. Pure PEEK can be sterilized using convenient sterilization methods (steam, dry heat, ethanol and Y-ray), and the raw material composition of PEEK complies with EU and US FDA regulations on food compliance, making it suitable for medical, pharmaceutical and food processing industry.

2.HONYPLAS®PEEK PTFE: Black, the result of adding PTFE, graphite and carbon fiber, makes it a bearing-grade plastic, its superior friction performance (low friction coefficient, wear resistance, higher peak pressure limit) .

3.HONYPLAS®PEEK 30GF: Brown-gray, the material is filled with 30% glass fiber reinforced plastic, which has better rigidity and creep resistance than pure PEEK, and better dimensional stability. It is the best choice for manufacturing structural parts. Can withstand a fixed load for a long time at high temperatures

4.HONYPLAS®PEEK 30CF: Black, this material is filled with 30% carbon fiber reinforcement, has better mechanical properties (higher elastic modulus, mechanical strength and creep) and more wear resistance than PEEK 30GF, and carbon fiber reinforced plastic is better than unreinforced plastic PEEK's plastic has 3.5 times the thermal conductivity to dissipate heat from the bearing surface faster

HONYPLAS®PEEK Virgin HONYPLAS®PEEK PTFE HONYPLAS®PEEK 30GF HONYPLAS®PEEK 30CF

HONYPLAS®PEEK Product Technical Properties Data Sheet

| Item | Test standard or instrument | Unit | PEEK Virgin(100%Virgin) | PEEK 30CF(30% carbon fiber) | PEEK 30GF(30% glass fiber) | PEEK PTFE (30%carbon fiber + graphia + PTFE) |

| Mechanical Properties | ||||||

| Tensile strength(23℃) | ISO 527 | MPa | 90 | 210 | 155 | 134 |

| Bending strength(23℃) | ISO 178 | MPa | 163 | 298 | 212 | 186 |

| Compressive strength(23℃) | ISO 604 | Mpa | 118 | 240 | 215 | 150 |

| Lzod impact strength | ISO 180/IU | KJ/m2 | No break | 40 | 51 | 32 |

| Thermal Properties | ||||||

| Melting point | ISO 11357 | ℃ | 343 | 343 | 343 | 343 |

| Distortion temperature | ISO 75-f | ℃ | 163 | 315 | 315 | 293 |

| Continuous using temperature | UL 74685 | ℃ | 260 | 260 | 260 | 260 |

| Coefficient of thermal expansion | ASTM D696 | 10-5℃ | 4.7 | 1.5 | 2.2 | 2.2 |

| Flammable level | UL 94 | V-0@mm | 1.5 | 1.5 | 1.5 | 0.75 |

| Electrical Properties | ||||||

| Dielectric strength | IEC 60243-1 | KV/mm | 18 | | 19 | |

| Dielectric constant | IEC 60250 | - | 3.2 | | 3.3 | |

| Surface resistivity | IEC 90093 | Ω | 10^15 | 10^5 | 10^15 | 10^6 |

| Other performance | ||||||

| Density | ISO 1183 | g/cm3 | 1.3+-0.02 | 1.4+-0.02 | 1.5+-0.02 | 1.43+-0.02 |

| Rockwell hardness | ISO 2039 | HRR | 118 | 121 | 119 | 108 |

| Friction coefficient | ASTM D3702 | - | 0.30-0.38 | 0.28 | 0.38-0.46 | 0.18 |

| Water absorption (25℃ 24Hrs) | ISO 62 | % | 0.15 | 0.06 | 0.11 | 0.06 |

| Mould shrinking percentage | 3mm 170℃ Flow direction | % | 1.2 | 0.1 | 0.4 | 0.3 |

| Perpendicular to direction | % | 1.5 | 0.5 | 0.8 | 0.5 | |

PEEK rods produced by the continuous extrusion process are more suitable for small batches and large-scale products to be produced by machining. PEEK rods with a diameter of 5-250mm can be extruded, and the length is generally 1000 or 2000 or 3000, can also be cut according to customer requirements, there are nearly a hundred kinds of extrusion dies with diameter specifications, and the inventory is complete

HONYPLAS®PEEK Rod Size

| Material | Diameter(mm) | Length(mm) | Color |

| PEEK Virgin | 5-250 | 1000,2000,3000 | Natural,Black |

| PEEK 30CF | 5-250 | 1000,2000,3000 | Natural,Black |

| PEEK 30GF | 5-250 | 1000,2000,3000 | Natural,Black |

| PEEK PTFE | 5-250 | 1000,2000,3000 | Black |

| ESD PEEK | 5-250 | 1000,2000,3000 | Natural |

HONY introduced imported PEEK profile extrusion production line to extrude 1250mm wide PEEK sheet to meet the demand of large-size PEEK parts in valve and other industries for ultra-wide PEEK sheet, better improve production efficiency and improve the quality of PEEK products. At the same time, the material utilization rate of the wide plate is very high when the typesetting cutting machine is processed.

HONYPLAS®PEEK Sheet Size

| Material | Width(mm) | Thickness(mm) | Length(mm) | Color |

| PEEK Virgin | 600-1250 | 6-60 | 1000,2000,3000 | Natural,Black,Red,Yellow |

| PEEK 30CF | 600-1250 | 6-60 | 1000,2000,3000 | Natural,Black,Red,Yellow |

| PEEK 30GF | 600-1250 | 6-60 | 1000,2000,3000 | Natural,Black,Red,Yellow |

| PEEK PTFE | 600-1250 | 6-60 | 1000,2000,3000 | Natural,Black,Red,Yellow |

| ESD PEEK | 600-1250 | 6-60 | 1000,2000,3000 | Black |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.