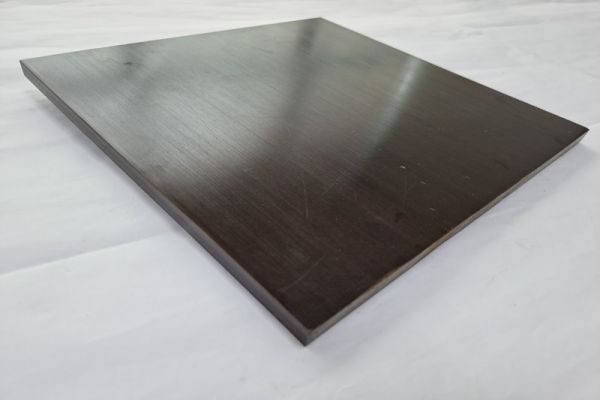

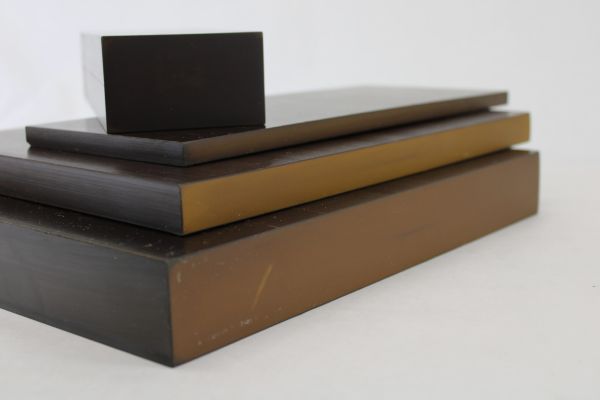

Torlon ® 5030 Glass Filled PAI Extruded

Get Latest Price| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Min. Order: | 1 Kilogram |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Min. Order: | 1 Kilogram |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Model No.: Torlon ® 5030 Glass Filled PAI

Brand: TORLON

| Selling Units | : | Kilogram |

| Package Type | : | Export package |

The file is encrypted. Please fill in the following information to continue accessing it

Torlon®5030 Stronger and Tougher than PEEK and polyimide from cryogenic to 500°F,Torlon 5030 is a high modulus polyamide-imide containing 30% glass fibers well suited for highly loaded structural parts plus electrical insulators and thermal isolators operating at temperatures above 300°F. It offers a 50% lower CLTE than non-reinforced Torlon 4203 but without the conductivity of carbon fibers. Its CLTE is similar to aluminum. The strength and creep resistance of 5030 is unmatched among high temperature polymers above 300°F and its modulus second only to Torlon 7130 over its operating range.

Torlon®5030 is a 30% glass-fiber reinforced grade of polyamide-imide(PAI)resin.It offers high strength and modulus and exceptional creep resistance.It has thermal expansion characteristics similar to aluminum and therefore excellent dimensional stability.

Torlon PAI has the highest strength and stiffness of any thermoplastic up to 275℃(525℉).It has outstanding resistance to wear, creep and chemicals.

The mechanical properties of torlon 5030 resin make it a candidate for metal replacement in high terperature , high stress applications. In addtional , it offers outstanding electrical properties, which makes it ideal for high performance parts such as connectors , switches and relays.

High Flow : Torlon 5030 - HF

Low Flow : Torlon 5030 - LF

Extrusion Grades : Torlon 5030-E

Torlon®5030 is ideal for:

High temperature thermal/electrical insulators

Test sockets for IC’s

Fasteners

Activation balls and valve seats

Key Properties

Thermal Performance to 500°F (260°C) Continuous Use Temp

Glass Reinforced Grade

Higher Strength and Modulus

Exceptional Creep Resistance

Low Coefficient of Linear Thermal Expansion (CLTE)

Limitations

Torlon® PAI has a relatively high moisture absorption rate, parts used in high temperatureservice or made to tight tolerances should be kept dry prior to installation. Thermal shock resulting indeformation can occur if moisture laden parts are rapidly exposed to temperatures above 400°F (205° C).

Applications

Aerospace Structural Components

Aircraft Structural Components

Business Equipment Components

Electrical Components

Structural Components

Typical Properties of Torlon ® 5030 Glass Filled PAI Extruded

| Description | Value | ||

| Material Type | Imidized Amorphous Thermoplastic | ||

| Chemical Name | PAI Polyamide-imide | ||

| Trade Name | Torlon®5030 | ||

| Additives | 30% Glass Filled | ||

| Color | Black | ||

| PHYSICAL | |||

| Property | Test | Unit of Measure | Value |

| Density | ASTM D792 | g/cm³ | 1.6 |

| ASTM D792 | lb/in³ | 0.058 | |

| Water Absorption, 24 hrs, Immersion | ASTM D570 | % by wt. | 0.3 |

| Water Absorption, Saturation, Immersion | ASTM D570 | % by wt. | 1.5 |

| MECHANICAL | |||

| Property | Test | Unit of Measure | Value |

| Tensile Strength | ASTM D638 | psi | 23,000 |

| Tensile Modulus | ASTM D638 | psi | 1,000,000 |

| Tensile Elongation at Break | ASTM D638 | % | 4 |

| Flexural Strength | ASTM D790 | psi | 30,000 |

| Flexural Modulus | ASTM D790 | psi | 980,000 |

| Compressive Strength | ASTM D695 | psi | 40,000 |

| Compressive Modulus | ASTM D695 | psi | 700,000 |

| Hardness | ASTM D785 | NA | Rockwell E90 |

| IZOD Impact-Notched | ASTM D256 | ft-lb/in | 1 |

| THERMAL | |||

| Property | Test | Unit of Measure | Value |

| Coefficient of Linear Thermal Expansion | ASTM D696 | x 10-5 in./in./°F | 0.9 |

| Heat Deflection Temp | ASTM D648 | °C at 264 psi | 277 |

| ASTM D648 | °F at 264 psi | 530 | |

| Max Continuous Operating Temp | °C | 260 | |

| °F | 500 | ||

| Minimum Operating Temp | °C | -200 | |

| °F | -328 | ||

| Thermal Conductivity | ASTM C117 | BTU-in/ft²-hr-°F | 2.5 |

| Flammability Rating | UL94 | NA | V-0 |

| ELECTRICAL | |||

| Property | Test | Unit of Measure | Value |

| Dielectric Strength | ASTM D149 | V/mil | 700 |

| Dielectric Constant at 1 MHz | ASTM D150 | NA | 4.4 |

| Dissipation Factor at 1 MHz | ASTM D150 | NA | 0.05 |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.