What is anti-static bakelite? Bakelite is a man-made synthetic chemical substance that once heated and molded, solidifies and can no longer be shaped into anything else, due to its non-absorbent, non-conductive, high temperature resistant, high strength and other characteristics, plus it is widely used in electrical products, hence the name. Bakelite boards now have an important use in machinery mold manufacturing, electronics, electrical appliances business. The reason for today's achievements, with its performance parameters are inseparable.

Main applications: PCB drilling, jigs and fixtures, switchboards, mechanical parts, test benches, SMT technical workbenches. Characteristics: All parts of the antistatic bakelite board have the same antistatic value, and the overall resistance value is 10^8-10^10Ω, which has stable antistatic performance. No change in anti-static value after mechanical processing or surface abrasion. Resistant to organic solvents, insoluble at room temperature, the use of temperature -20-120 ℃ high mechanical strength, excellent processing performance.

Use of bakelite board: bakelite board because of insulation, does not produce static electricity, wear-resistant and high-temperature resistance and other characteristics, to become an insulated switch of electronic products and variable resistance, mechanical molds and fixtures on the production line, and can be used in the transformer oil used in products such as the use of. Electrician laminated wood board is widely used in transformers, transformers in the insulation, support materials. It has the advantages of moderate specific gravity, high mechanical strength, easy vacuum drying, easy mechanical processing, and its dielectric constant is close to that of transformer oil, and the insulation is reasonable, so it can be used for a long period of time in the transformer oil at 105℃.

Electrician laminated wood board in oil-immersed transformer has been widely used to manufacture upper and lower pressure plate, lead bracket, iron yoke pads and other parts, in the mutual inductor used to make the clamping parts, it replaces the steel plate, insulating cardboard, epoxy cardboard, epoxy glass cloth board in these applications, thus reducing the transformer weight and material costs. Electrical laminated wood board is made of veneer made of high-quality birch wood by steaming, rotary cutting and drying, coated with special insulating glue, and then made by high temperature and high pressure.

All parts of antistatic bakelite panels have the same antistatic value, and the overall resistance value is 10^8-10^10Ω, with stable antistatic performance.

After mechanical processing or surface abrasion, the anti-static value has no change.

Resistant to organic solvents, insoluble at room temperature, the use of temperature -20-120 ℃ high mechanical strength, excellent processing performance.

ESD Bakelite Sheet is a kind of antistatic materials which is added anti-static agents in the production of Bakelite sheet, and effect Bakelite to achieve the best antistatic performance. A substrate is a phenolic resin and electric grade bleached wood pulp paper. ESD Bakelite sheet provides a uniform anti-static value. The surface and volume resistivity value are 106-109Ω. And the antistatic value will not be changed after machining or surface grinding.

ESD Anti-Static Phenolic Bakelite Sheet

Industrial laminates are thermoset resin impregnated reinforcing materials (paper, cotton fabric, glass fabric, etc.) that are cured under heat and pressure to form solid shapes having high mechanical and electrical insulating properties. Laminates are available in sheet, rod, and tubes. Since laminates are comprised of a combination of materials, they are also referred to as composites.

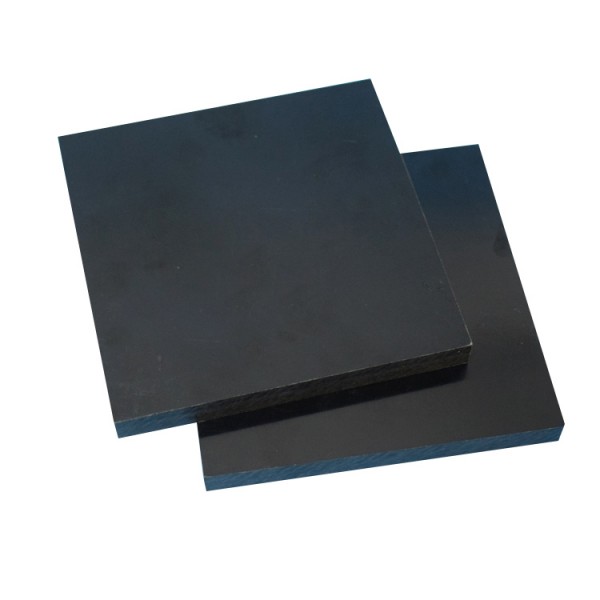

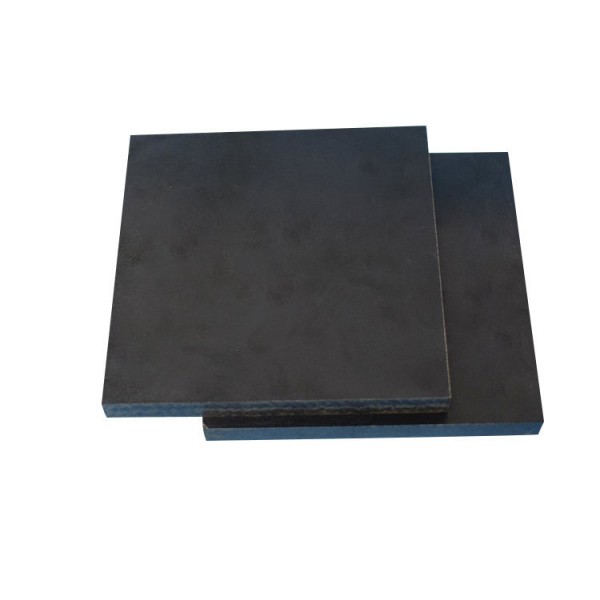

Thickness(mm)

Width*Length(mm)

3-30mm

1020mmX1220mm, 1000*2000mm

Name: Bakelite Sheet

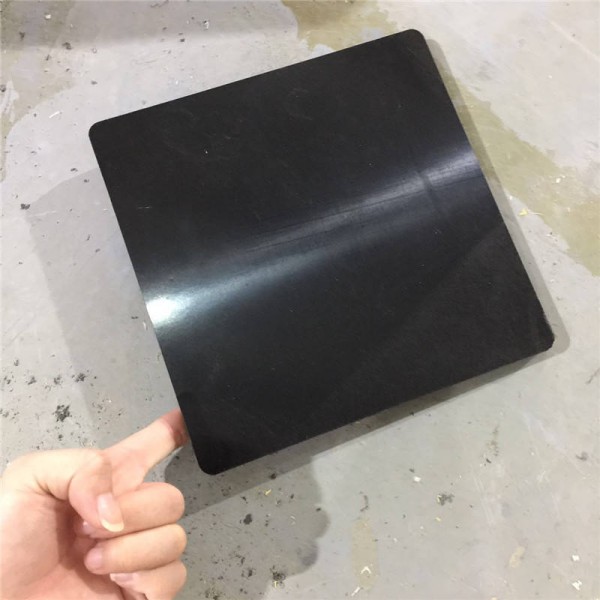

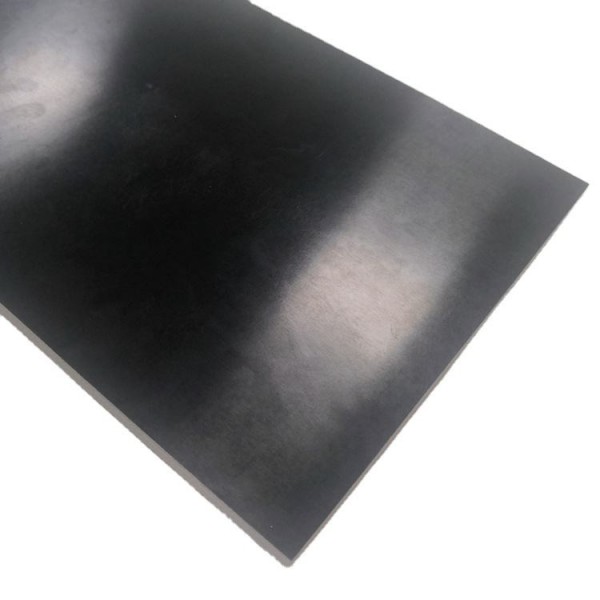

Colors include: Black

Types: Sheets

ESD Antistatic Bakelite Features:

1. Extremely stable anti-static properties,

2. Good mechanical strength,

3. Good anti-static properties, Good intermediate electrical insulation, non-conductive,

4. Resistance to organic solvents.

ESD Antistatic Bakelite Applications:

1. The mobile phone test fixture, SMT technology countertops, PCB drilling.

2. The semiconductor test fixture, semiconductor crystal manufacturing equipment parts.

3. The wafer processing jig, sensitive electronic components, the hard disk drive means.

4. The printed circuit boards, high-precision automated fixtures.

5. The installation of electronic equipment, fixtures, etc.