HONY®bakelite-Taiwan Syndyne Syndyne uses the phenolic resinWikipedia Phenolic Resin (one of the oldest type of polymeric resinous binders) and adopts a superb technology to produce the phenolic resin laminates, also known as “phenolic laminateWikipedia Phenolic Laminate” – the world's oldest industrial laminates.

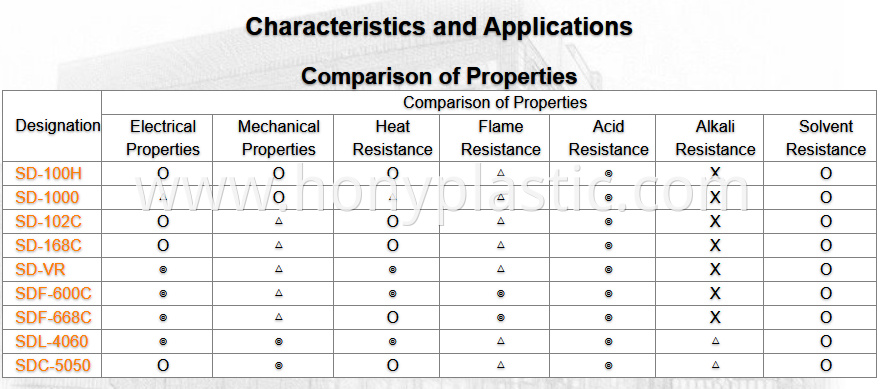

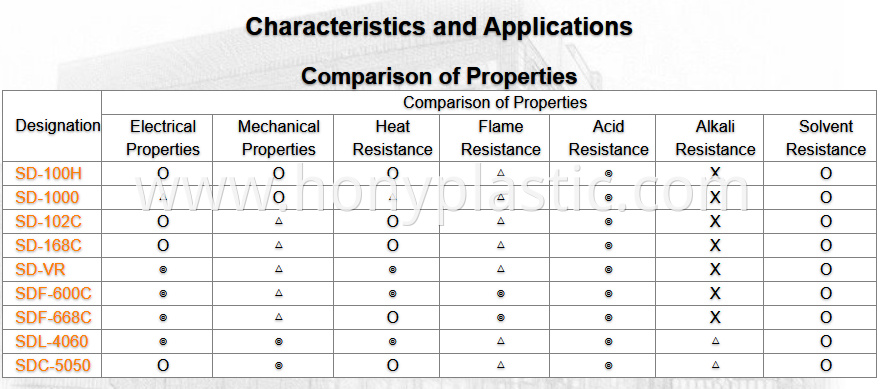

From resin reaction, impregnation of paper or fabric, weighing and building up, hot pressing, fabrication, packing and inspection, to warehouse stock,phenolic laminates are produced with unique heat resistant, flame resistant, acid resistant and electrical insulating properties.

There is a wide use of paper-based phenolic laminate, including the florescent light caps, plugs, switches, radio parts, car parts that we use daily, to electrical distribution boards, supersonic machinery that is used in the industry. Phenolic laminate, in general, has excellent electrical insulation property and mechanical property.

Fabric-based phenolic laminate combines a modified phenolic resin and a heavy- or fine-woven cotton fabric as reinforcement. It is highly heat resistant and does not creep under high temperature. Fabric-based phenolic laminate has superb mechanical property, with their toughness and high impact strength it allows the fabrication of gears/cogs and pulleys. This type of gears and pulleys are hard-wearing, has relatively low noise and prolong the life span of the machinery.

Another type of Phenolic Resin Laminate is called the phenolic resin back-up board, where it is used as the protective entry and/or back-up board while drilling or routhing of flexible and/or rigid printed circuit boards (PCB).

Our phenolic laminates have a thickness range from 0.2mm to 100mm, and a wide range of dimensions suitable for all applications. Syndyne's thin-type (<2.5mm) phenolic laminate can be used in hot-, warm-, or cold-punching; while thick-type (>2.5mm) phenolic laminate can be easily processed by various methods, such as sawing, planing, milling, lathing, grinding, and drilling etc.

All these phenolic resin laminates/rods/tubes, PCB back-up boards and other industrial plastic materials have received the UL certification, passed the SGS testing and in 2006, attained ISO 9001 quality standard certification.

Specific gravity g/cm 1.45

Temperature resistance (continuous) °C 140

Temperature resistance (short time) °C 300

Water absorption % <1.5

Coefficient of linear thermal expansion Kx 10

Flammability (UL94) 94HB

Vertical layer bending strength MPa ≥120

Vertical layer direction compressive strength MPa ≥250

Tensile strength MPa ≥100

Impact strength kJ/m 67

Adhesive strength N 3600

Insulation resistance after immersion Ω 1.0*10

Vertical layer direction electric strength KV/m 12.1

Parallel layer breakdown voltage KV 10

Relative permittivity (1MHz/50Hz) 5.5/-

Volume resistance 10-7~10-8Ω x cm

Phenolic Cloth Esd Bakelite Sheet is the most common laminate, and it is also the most widely used and most used industrial laminate in the world.

The paper bakelite produced by Syndyne uses high-quality bleached wood fiber paper and cotton linter paper as reinforcements, and is made of phenolic resin made from high-purity, fully synthetic petrochemical raw materials as a resin binder. , With excellent electrical, mechanical and processing properties

Syndyne’s paper bakelites are traditionally divided into hot stamping, warm stamping, cold stamping and thick plate (not suitable for stamping processing) according to the user’s processing methods; among them, the preheating conditions before stamping processing, please refer to the following Table, as for the thick plates that are not suitable for stamping processing, they can be competent for various processing methods such as sawing, planing, milling, turning, grinding, and drilling.

Esd Bakelite Sheet Main Production

Esd Anti-Static Phenolic Paper Laminate Technical

Package