Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand:Acetron

Min. Order:1 Kilogram

Model No:Acetron®Food Grade Blue 50 POM-C

Transportation:Ocean,Land,Air,Express

Packaging:Export package

Supply Ability:1000

Acetron® Food Grade Blue 50 POM-C is compliant in both Europe and North America, which is one of the key competitive advantages that it offers to the Food Processing industry. For companies that are exporting, this is critical as they will now only...

Brand:Sustarin

Min. Order:1 Kilogram

Model No:Sustarin® (POM)

Transportation:Ocean,Land,Air,Express

Packaging:Export package

Supply Ability:100

SUSTARIN® C (Acetal) is a general-purpose porosity free copolymer acetal. SUSTARIN® C is easily machined with excellent dimensional stability for close tolerance parts. Key properties include a low coefficient of friction and excellent wear...

Brand:HONY

Min. Order:1 Kilogram

Model No:HONY-POM plus 30PTFE

Transportation:Ocean,Land,Air,Express

Packaging:Export carton pallet

Supply Ability:Enough

HONY®POM-30PTFE is made by blending POM and PTFE materials, which retains most of the strength of POM. After the addition of PTFE, the material properties change, softening, less rigidity, and smoother surface.Product features: low friction...

Brand:HONY

Min. Order:1 Kilogram

Model No:HONY-POM

Transportation:Ocean,Land,Air,Express

Packaging:Export carton pallet

Supply Ability:Enough

Acetal Pom Sheet HONYPOM is a thermoplastic material with excellent fatigue resistance, creep resistance, self-lubricating properties and mechanical processing properties. It can be used for a long time at a temperature of -40℃-100℃. Product...

Brand:Delrin

Min. Order:1 Kilogram

Model No:Delrin AF 20% PTFE filled Acetal

Transportation:Ocean,Land,Air,Express

Packaging:Export package

Supply Ability:100

TECAFORM AD AF natural is a POM homopolymer with special PTFE fibres designed to optimize the material's sliding friction properties. The fibres are homogenously distributed in the acetal material, and results in an improved slide-friction...

Brand:TECAFORM

Min. Order:1 Kilogram

Model No:TECAFORM® HPV13 brown homopolymer acetal

Transportation:Ocean,Land,Air,Express

Packaging:Export package

Supply Ability:10000

TECAFORM® HPV13 is a brown homopolymer acetal with an internal PTFE lubricant. Its low coefficient of friction, excellent PV values, toughness, wear resistance, and machinability make it an exceptional material for use in many industrial and...

Brand:TECAFORM®

Min. Order:1 Kilogram

Model No:TECAFORM® AH natural POM-C UNFILLED

Transportation:Ocean,Land,Air,Express

Packaging:Export package

Supply Ability:100000

Place of Origin:Germany

TECAFORM AH natural acetal is an unfilled porosity free POM-C with a unique balance of physical properties not available in most other thermoplastics. This copolymer acetal is an engineering plastic made for wide-ranging universal applications in...

Brand:HONY

Min. Order:1 Kilogram

Model No:HONY-POM MoS2

Transportation:Ocean,Land,Air,Express

Packaging:Export carton pallet

Supply Ability:Enough

Productivity:10000

HONY®POM-MoS2 is a special wear-resistant engineering composite material mixed and extruded with polyoxymethylene (POM) and molybdenum disulfide wear-resistant particles. This material is more wear-resistant than pure POM.Product features: super...

Brand:HONY

Min. Order:1 Kilogram

Model No:HONY-DELRIN

Transportation:Ocean,Land,Air,Express

Packaging:Export carton pallet

Supply Ability:Enough

HONY®Engineering Plastics Acetal Delrin POM Rod Sheet Plate , 10-100mm polyoxymethylene delrin pom sheet Low friction coefficient Polyacetal sheet,delrin sheet What is Polyacetal sheet ?Delrin sheet is a kind of engineering plastic with good...

Brand:HONY

Min. Order:1 Kilogram

Model No:HONY-POM

Transportation:Ocean,Land,Air,Express

Packaging:Export carton

Supply Ability:100000

Productivity:100000

HONY®POM have good mechanical properties and rigidity, and close to the metal material. It’s an ideal replacement material of copper, cast zinc, steel, aluminum and other metal materials. Excellent fatigue resistance and creep resistance. Good...

Brand:HONY

Min. Order:1 Kilogram

Model No:HONYPOM-CONDUCTIVE

Transportation:Ocean,Land,Air

Packaging:Export carton pallet

Supply Ability:Enough

Production description :HONYPOM-CONDUCTIVE is a conductive material made after modification with polyoxymethylene as the base material. The anti-static value of all parts is 104-105, and the anti-static value does not change after friction or...

Brand:HONY

Min. Order:1 Piece/Pieces

Model No:HONY-POM

Transportation:Ocean,Land,Air,Express

Packaging:Export carton pallet

Supply Ability:Enough

Production description: HONYPOM bar is extruded at a high temperature by an extruder through POM plastic particles, and extruded through a corresponding die to obtain bars of different thicknesses. It is a high melting point, high crystalline...

Brand:Delrin

Min. Order:1 Kilogram

Model No:DELRIN®150

Transportation:Ocean,Land,Air,Express

Packaging:Export package

Supply Ability:100000

Delrin® 150 is a homopolymer acetal that is manufactured by Ensinger (using DuPont™ Delrin® resin) and sold under the trade name TECAFORM AD natural. This homopolymer acetal has exceptional sliding characteristics and good wear resistance...

USD 3.7 ~ USD 3.9

Model No:HONY-ACETAL

Transportation:Ocean,Land,Air

Supply Ability:Enough

HONY®Acetal sheet rod 10-100mm black acetal sheet, POM is a kind of dystectic, high crystallinity thermoplastic engineering plastic material, its mechanical property is very close to metal material, can be used in 100°C normally.POM sheet can be...

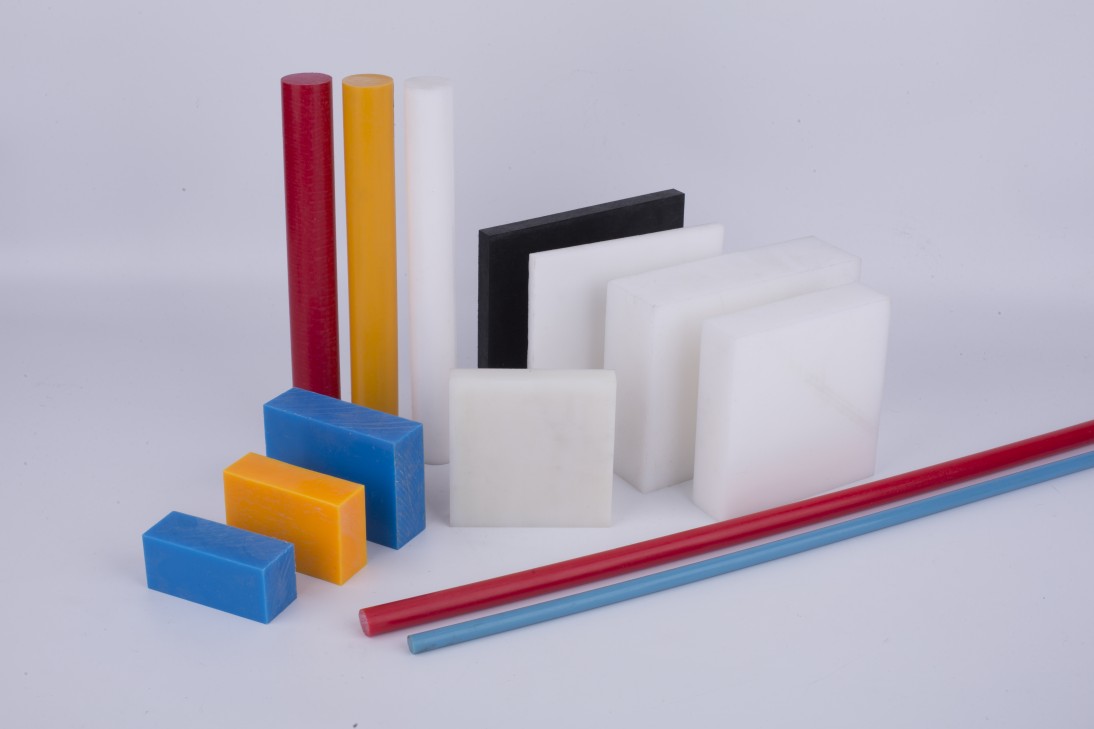

HONY®POM sheet rod is usually called acetal (chemical name is polyoxymethylene). HONY plastic can provide POM extruded sheets, bars and pipes, which can be used for machining. POM plastic is a semi-crystalline thermoplastic with high mechanical strength and rigidity. POM plastics have good sliding properties, excellent wear resistance and low moisture absorption. Good dimensional stability, excellent fatigue strength and excellent processing ability make POM material a highly versatile engineering material, even for complex components.

The performance of homopolyoxymethylene (POM-H) and copolyoxymethylene (POM-C) is different. Due to the higher crystallinity, the density, hardness and strength of POM-H materials are also slightly higher. However, compared to POM-H materials, POM-C materials have better chemical resistance, but have a lower melting point.

HONY can provide POM material shapes including:

POM rod

POM board

POM pipe

Delrin® is a registered trademark of E.I. du Pont de Nemours.

POM sheet rod Feature

High mechanical strength, stiffness and hardness

Excellent toughness

Good creep resistance

High impact strength, even under low temperature conditions

Good dimensional stability (low water absorption)

Good sliding performance and wear resistance

Superior machining performance

Good electrical insulation and dielectric properties

Physiologically inert (most grades are suitable for contact with food)

Non-self-destructive

Acetal Sheets and Acetal Rods Application

Small module gear

Cam

Heavy-duty bearings and rollers

Small clearance bearings and gears

Valve seat

Dimensionally stable precision parts

Electrical insulation parts

Swipe application

Excellent design solution for bayonet fasteners

Sliding parts such as bearing bushes, rollers and slide rails

Electrically insulating parts

Parts in contact with water

Scratch-resistant high-gloss parts

Various components in the food, pharmaceutical and drinking water industries and medical technology

Acetron® / Ertacetal®

Ertacetal® / Acetron® is family of acetals with greater dimensional stability than polyamides despite having a lower wear resistance. Mitsubishi Chemical Group offers both homopolymer and copolymer grades of POM. Special formulations include an enhanced bearing grade material, a metal- and x-ray-detectable acetal, food-contact compliant acetals, and a range of colors.

In general, acetals do not perform as well in abrasive wear applications as nylons. However, Ertacetal® / Acetron® offers a range of excellent performance attributes including high mechanical strength, stiffness, and hardness, great resilience and resistance to creep, high impact strength at low temperatures, low water absorption for great dimensional stability, and food-contact compatibility.

Products in the Acetron® / Ertacetal® family (8)

POM-C (6)

POM-H (2)

Acetron® GP FG / Ertacetal® C FG POM-C

Copolymer Polyoxymethylene

Acetron® GP Polyoxymethylene POM-C FG (Food Grade) / Ertacetal® C Polyoxymethylene POM-C FG (Food Grade) is a general purpose, copolymer acetal grade that is favored for its porosity free nature, as well as its higher resistance to hydrolysis, strong alkalis, and thermal oxidative degradation than homopolymer acetal grades. These food grade, POM-C shapes also offer low moisture absorption and excellent machinability capabilities, making it a very versatile material that can excel in a multitude of environments. Due to these characteristics and their compliance with compositional FDA 21 CFR § 177.2470, EU 10/2011, USDA, NSF, Canada AG, and 3A-Dairy requirements, components made from this material are used frequently for food contact applications.

Material Properties

Porosity free

Great resistance to hydrolysis, strong alkalis, and thermal oxidative degradation

Low moisture absorption

Excellent machinability

Food contact compliant

Acetron® VMX Food Grade POM-C

Copolymer Polyoxymethylene

Acetron® VMX Food Grade POM-C is an EU 10/2011 and compositional FDA 21 CFR § 177.2470 compliant copolymer acetal containing metal and x-ray detectable additives and has bright blue coloring for ease of visual detection. This material has been specifically tailored for use in the food processing and packaging industries where it can easily be traced by different detection systems installed to detect physical contamination in foodstuffs. Additionally, Acetron® VMX Food Grade presents good mechanical strength, stiffness, and impact strength, making this grade especially well-suited for different applications like gears, scrapers, grippers, etc

Material Properties

Three-way detectability: visual, metal, x-ray

EU 10/2011 and compositional FDA 21 CFR § 177.2470 compliant

Good mechanical strength

Good mechanical stiffness

Impact resistant

Ertacetal® C ELS POM-C

Copolymer Polyoxymethylene

Ertacetal® C ELS is a copolymer acetal whose shapes exhibit excellent electrical conductivity qualities, low moisture absorption, high strength and stiffness, and great machinability capabilities. This grade in particular is recommended for use in electrical and explosion sensitive applications.

Material Properties

Excellent electrical conductivity

Low moisture absorption

High strength and stiffness

Great machinability

Ertacetal® C LQ POM-C

Copolymer Polyoxymethylene

Ertacetal® C LQ is a white/natural-colored copolymer polyoxymethylene specifically developed for laser writability via IR-YAG and UV-YAG technologies. The acetal copolymer itself is more resistant to hydrolysis, strong alkalis, and thermal-oxidative degradation than the homopolymer acetal grade, and offers identical physical properties and machinability to the standard Acetron® GP / Ertacetal® C POM-C, including low moisture absorption and porosity-free composition.

Material Properties

Laser writeable via IR-YAG, UV-YAG, etc.

Resistant to hydrolysis, strong alkalis, and thermal-oxidative degradation

Porosity free and low moisture absorption

Excellent machinability

Acetron® AF Blend / Ertacetal® H-TF POM-H

Homopolymer Polyoxymethylene

Acetron® AF Blend / Ertacetal® H-TF POM-H is a unique thermoplastic material for use in moving parts in which low friction and long wear resistance are important. The material has a high strength, toughness, dimensional stability and good machinability as well as improved wear characteristics over unfilled POM-H. Unblended Acetron® AF Blend / Ertacetal® H-TF POM-H offers a slightly higher limiting PV and lower coefficient of friction due to additional PTFE content. This added PTFE typically decreases the wear capability and impact strength. Acetron® AF 100 is available on a custom basis.

Material Properties

Low friction, long wearing

High strength, toughness

High dimensional stability, machinability

Acetron® GP / Ertacetal® C POM-C

Copolymer Polyoxymethylene

Acetron® GP Polyoxymethylene POM-C / Ertacetal® C Polyoxymethylene POM-C is a general purpose, copolymer acetal grade that is often favored for its porosity-free nature. These POM-C shapes also offer low moisture absorption and excellent machinability capabilities, making it a very versatile material that can excel in a multitude of environments. Due to these characteristics, Acetron® GP / Ertacetal® C POM-C components are used frequently for food contact applications, and meet FDA, NSF, Canada AG, and SSI Standard compliance requirements.

Material Properties

Porosity free

Low moisture absorption

Excellent machinability

Acetron® / Ertacetal® H POM-H

Homopolymer Polyoxymethylene

Acetron® Polyoxymethylene POM-H / Ertacetal® H Polyoxymethylene POM-H is a homopolymer acetal grade that offers superior mechanical strength, stiffness, hardness, and creep resistance, in addition to a much lower thermal expansion rate and increased wear resistance when compared to copolymer acetal grades. Due to these characteristics, Acetron® POM-H / Ertacetal® H POM-H excel in a variety of applications including small diameter, thin-walled bushings and bearings, gears, electrical components, valves, and fluid handling components.

Material Properties

Excellent mechanical properties allows use of standard fasteners

Excellent stability and machining properties reduce machining cost

Durability of material allows easy installation and removal (low distortion)

Chemical resistance enables very long service lifetime

High impact strength, even at low temperatures

Very good dimensional stability (low water absorption)

Acetron® C Sterra™ POM-C

Copolymer Polyoxymethylene

Acetron® C Sterra™ is a general purpose, copolymer acetal grade with recycled contents that is often favored for its porosity free nature. This recycled POM-C also exhibits low moisture absorption and excellent machinability capabilities, making it a very versatile material that can excel in a multitude of environments.

As part of the Sterra™ product portfolio, Acetron® C Sterra™ contains recycled POM-C and therefore is associated with a significantly lower carbon footprint compared to similar materials derived from non-recycled feedstocks. For details, please refer to the respective environmental datasheet.

Material Properties Porosity-free Low moisture absorption Excellent machinability

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.