TECAPEEK MT medical grade PEEK sheet rod Ensinger

Get Latest Price| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,DDP |

| Min. Order: | 1 Kilogram |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Guangzhou,HongKong |

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,DDP |

| Min. Order: | 1 Kilogram |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Guangzhou,HongKong |

Model No.: TECAPEEK

| Selling Units | : | Kilogram |

| Package Type | : | Export package |

The file is encrypted. Please fill in the following information to continue accessing it

TECAPEEK®Polyetheretherketone (PEEK) are made exclusively with Victrex PEEK polymer. TECAPEEK is a unique, semi-crystalline, high-temperature engineering thermoplastic.It is an excellent material for a wide spectrum of applications where thermal, chemical, and combustion properties are critical to performance.

Especially significant in this regard is TECAPEEK's ability to retain its flexural and tensile properties at very high temperatures in excess of 250°C (482°F).

The addition of glass fiber or carbon fiber reinforcements enhances the mechanical and thermal properties of the basic TECAPEEK®material.

Excellent flexural, impact, and tensile characteristics

Very high continuous working temperature

Very high heat deflection temperature

For unreinforced TECAPEEK™, the HDT @264 psi is 152°C (306°F). The addition of 30% reinforcement results in a dramatic increase to 315°C (600°F).

Exceptional chemical resistance

TECAPEEK™ is insoluble in all common solvents.

A superior dielectric at high temperatures and frequencies

Good radiation resistance

TECAPEEK™ exhibits superior resistance to high doses of gamma radiation.

Outstanding wear and abrasion resistance

Low smoke and toxic gas emissions

Excellent hydrolysis resistance

TECAPEEK™ has an excellent resistance to hydrolysis in boiling water and superheated steam (sterilization/autoclavability) at temperatures in excess of 250°C (482°F).

TECAPEEK™s exceptional property profile enables it to be utilized in many of the most critical areas in general industry, as well as in the automotive, marine, nuclear, oil well, electronics, medical and aerospace fields.

Ensinger is a manufacturer of various PEEK modifications. All PEEK plastics are supplied as:

PEEK rod

PEEK sheet and plate

PEEK tube

Our partner

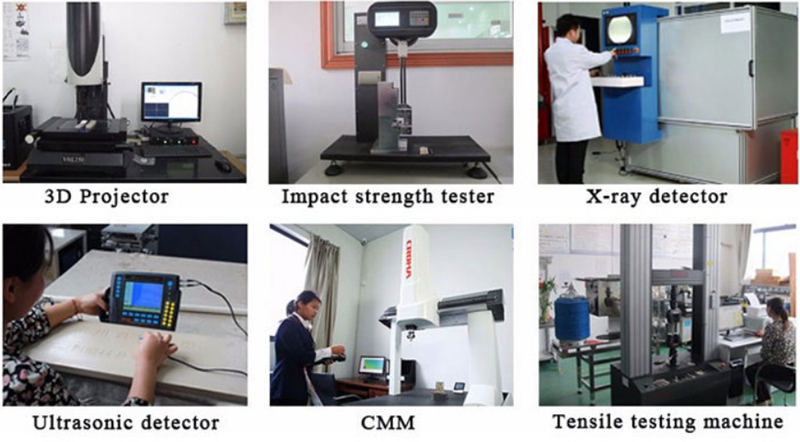

Our Test

Our package

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.