Acrylic anti-static sheet -- static electricity nemesis, the quality of choice

In today's era of rapid technological development, static electricity has become a challenge that many fields have to face. The emergence of acrylic antistatic plate, as a heroic static nemesis, with its excellent quality, for various industries to bring a reliable solution.

First, the danger of static electricity: the invisible threat that can not be ignored

Static electricity, a phenomenon often overlooked by us in our daily lives, but in many areas lurking in the great harm. In the electronics industry, electrostatic discharge may damage sensitive electronic components, resulting in equipment failure or even scrap. For example, in the integrated circuit manufacturing process, a small electrostatic discharge may damage the internal structure of the chip, resulting in irreparable damage. In the medical field, static electricity may interfere with sophisticated medical equipment, affecting the accuracy of diagnostic results and even posing a threat to the safety of patients' lives. In the chemical industry, static sparks may cause explosions and fires with unimaginable consequences. In addition, in the printing, textile, plastics and other industries, static electricity can also lead to product quality degradation, reduced productivity and other issues.

Second, the acrylic antistatic plate: a powerful opponent of static electricity

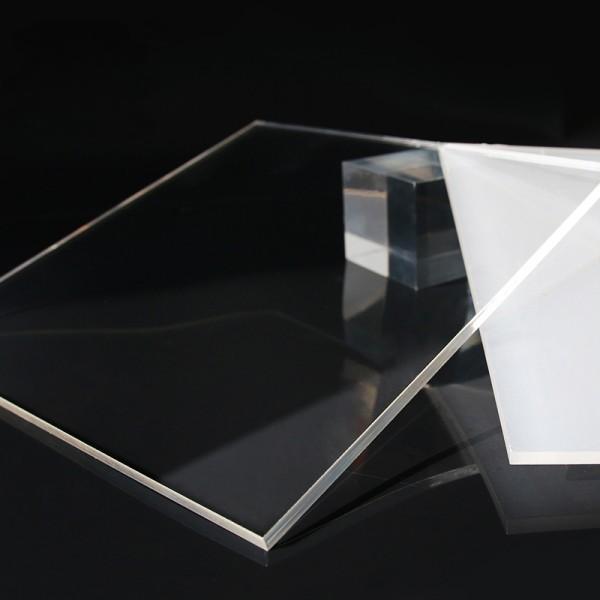

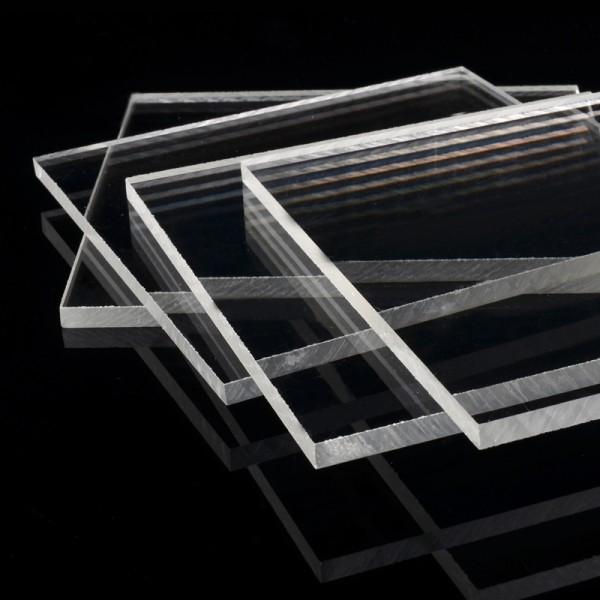

Acrylic antistatic plate, as a new type of material, with its unique performance has become the nemesis of static electricity. It uses a special process, so that its surface has good electrical conductivity, can quickly conductive static electricity away, effectively prevent the accumulation of static electricity and discharge. Compared with traditional antistatic materials, acrylic antistatic sheet has higher transparency, better mechanical strength and superior chemical resistance.

High transparency

Acrylic antistatic sheet has a very high transparency, almost comparable to ordinary glass. This gives it a unique advantage in situations where internal items need to be displayed. For example, in applications such as electronic equipment display cabinets and laboratory instrument covers, it provides protection against static electricity without interfering with the observation of internal items. Its high transparency also allows it to have a wide range of applications in the lighting field, such as the production of lampshades, light guides, etc., which can ensure the uniform transmission of light, but also prevent the impact of static electricity on the lamps and lanterns.

Good mechanical strength

Acrylic antistatic sheet has excellent mechanical strength, not easy to break, not easy to deform. This allows it to maintain stable performance in a variety of harsh environments. Whether it is bumps during transportation or collisions during installation and use, the acrylic antistatic sheet can withstand the test and provide reliable protection for the items being protected. At the same time, its good mechanical strength also makes it possible to carry out a variety of processing and molding to meet the individual needs of different customers.

Excellent chemical resistance

Acrylic antistatic sheet has good resistance to various chemicals and is not easily corroded by acids, alkalis and salts. This makes it widely used in chemical, pharmaceutical and other industries. In these industries, often come into contact with a variety of corrosive chemicals, ordinary materials are easily corroded and damaged, while the acrylic antistatic sheet is able to maintain stable performance for a long time, providing effective protection for equipment and products.

Wide range of applications

Due to its excellent performance and quality, acrylic antistatic sheet is widely used in many fields. In the electronics industry, it is used to manufacture electronic products shell, packaging materials, anti-static workbench, etc.; in the medical field, it is used to make medical equipment shell, protective masks, surgical instrument trays, etc.; in the chemical industry, it is used to make the chemical equipment shield, storage tanks, pipelines, etc.; in the field of advertising and display, it is used to make displays, light boxes, billboards and so on. It can be said that the acrylic antistatic plate has become one of the indispensable materials in various industries.