Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand:CIP

Min. Order:1 Kilogram

Model No:CIP Composites CIP131

Transportation:Ocean,Land,Air,Express

Packaging:Export package

Supply Ability:100

100% polyester material (textile and resin) with PTFE evenly dispersed throughout the resin system. Enhancement A is added, increasing the overall strength and reduce friction and wear. Key Properties Self lubricating Low coefficient of friction...

Brand:CIP Marine

Min. Order:1 Kilogram

Model No:CIP Marine

Transportation:Ocean,Land,Air,Express

Packaging:Export package

Supply Ability:100

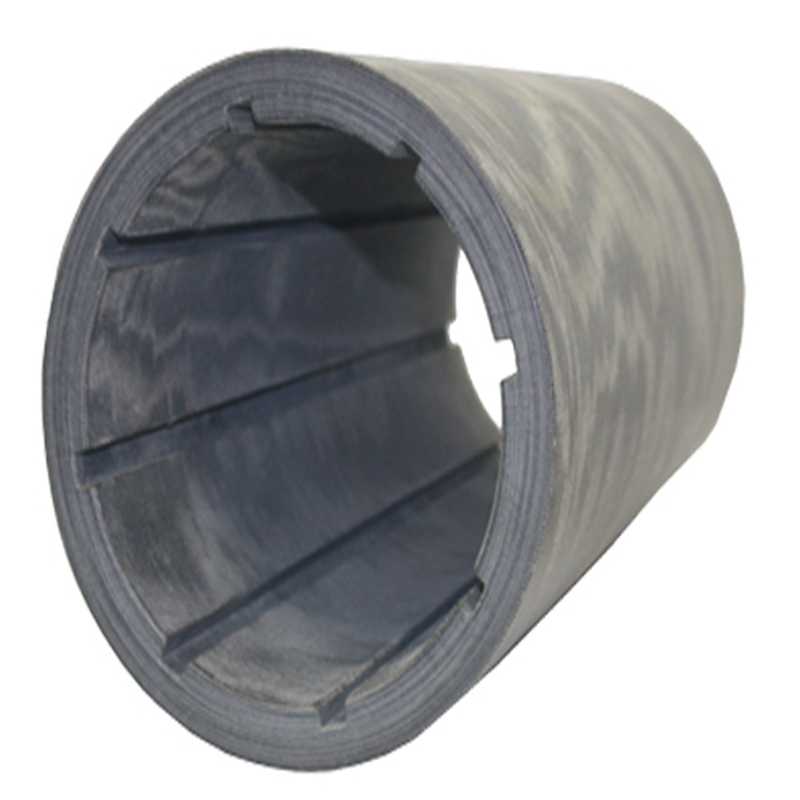

CIP Marine is manufactured with polyester textile and a high performance polyester resin with solid lubricants PTFE and molybdenum disulfide (MoS2) evenly dispersed throughout the resin. Typically used as propeller shaft and rudder bushings. CIP...

USD 12 ~ 15

Brand:CIP composites

Min. Order:1 Kilogram

Model No:CIP composite

Transportation:Ocean,Land,Air,Express

Packaging:Export carton

Supply Ability:Enough

Place of Origin:United State

Columbia Industrial Products offers multiple textile, lubrication and resin combinations to provide the most suitable material for your application. Below are the most common CIP Composite material grades. Our dedicated team will help you choose...

Brand:CIP

Min. Order:1 Kilogram

Model No:CIP composite

Transportation:Ocean,Land,Air,Express,Others

Packaging:Export carton and box

Supply Ability:1000

Place of Origin:United States

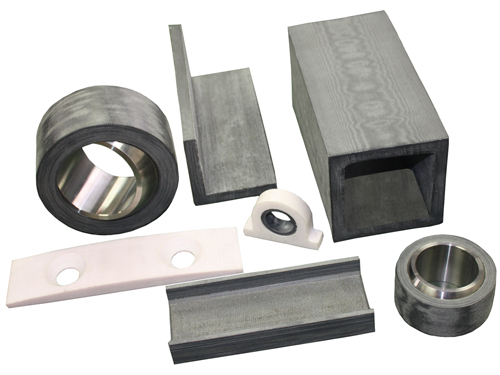

CIP Composites are available in tubes or sheets made to your specification. CIP Composites are readily machinable by conventional machining techniques. As a general guide they may be treated as bronze, but machined (dry) without coolant. CIP...

Brand:CIP Composite

Min. Order:1 Kilogram

Model No:CIP Composite

Transportation:Ocean,Land,Air,Express

Packaging:Export carton and box

Supply Ability:1000

Place of Origin:United States

Cip Composite Material are available in tubes or sheets made to your specification. CIP Composites are readily machinable by conventional machining techniques. As a general guide they may be treated as bronze, but machined (dry) without coolant. CIP...

Columbia Industrial Products offers multiple textile, lubrication and resin combinations to provide the most suitable material for your application. Below are the most common CIP Composite Material grades. Our dedicated team will help you choose which CIP material will best fit your specific application, taking into consideration the type of environment (wet/dry, dirty/caustic), amount of load, speed of moving parts, and temperature among other factors.

CIP HYDRO

Specifically designed for Hydro Power environments

Tested by PowerTech Labs and approved by the US Army Corps of Engineers

Replaces bronze, polyurethanes, nylon, oil lubricated babbitt and wood

CIP MARINE

Specifically developed for marine environments

ABS and RINA approvals for rudder and stern tube bearings

Replaces bronze, polyurethanes, nylon, oil lubricated babbitt and wood

TEROTUF

Knife and gun grip material

Available in 12 colors

Weather tested by Ochs Sherworx

100 SERIES MATERIALS

CIP 100 series materials offer the widest range of lubricant options and support most applications.

CIP101

No lubrication

Designed for static applications

Commonly used as an electrical insulator

Low cost

CIP111A

Ideal for indoor applications

Low maintenance

Cost effective

CIP121A

Good load capacity

Good wear performance

Commonly used as wear pads, thrust washers and bushings

CIP131A

Stable in hydraulic fluids

Chemically resistant

#1 CIP material for hydraulic wear rings. Also commonly used in food processing equipment requiring harsh chemical wash downs.

CIP151A

Improved chemical resistance

Operating temperatures up to 400°F

Cost effective

CIP153A

Operating temperatures up to 400°F

Chemically resistant

CIP133A

Improved chemical resistance

Operating temperatures up to 400F

CIP152A

Excellent stability and strength

Works well in saltwater environments

Special blend originally designed for the oil and gas industry.

200 SERIES MATERIALS

CIP 200 series material provide the best tribological performance.

CIP251A

Ideal in high loads

Slow oscillating applications

Linear slide motion applications

CIP252A

Wet environments when sand and silt are present

Common applications include underwater salvage, remotely operated vehicles (ROV) and dredging equipment

300 SERIES MATERIALS

CIP 300 series material provide the best environmental performance.

CIP333A

Best chemical resistance

Operating temperatures up to 400°F

Commonly used in paving equipment, ejection molding and high temperature pumps.

CIP353A

Best chemical resistance

Operating temperatures up to 400°F

Common applications include down hole drilling, high temperature mining, and robotics.

Cip Composite are laminated polymer materials made by impregnating textiles with thermoset resins. Solid lubricants are added to the resin to provide evenly dispersed lubrication throughout the material, inherently eliminating the need for external lubrication. CIP offers customers an array of different textile, lubricant and resin combinations. We determine the best

combination based on application criteria and environment.

There are many benefits to CIP Composite materials. Those listed below are the most common benefits that are applicable in most applications, for a complete list visit our benefits page or visit our industry pages.

Self-lubricating

Solid lubricants are dispersed evenly throughout the material, eliminating the need for external lubrication. Offering a variety of advanced lubricants, additives and material combinations CIP can provide a product solution for a wide scope of application demands.

Replaces Bronze

CIP Composites are ideal for replacing traditional bronze and plugged bronze bearings. Metallic bearings require a consistent film of external lubrication for operation. CIP Composites can reduce or eliminate external lubrication systems with its self lubricating properties. Graphite plugged bronze bushings rely on full rotational movement to create an even lubrication layer. In slow oscillating applications, the lubrication layer may be uneven or non-existent and high friction or stick-slip can become a concern. CIP`s even distribution of lubrication additives allow for low dynamic and static coefficients of friction, eliminating stick-slip and noise.

100% Bearing Material

Cip Composite Material are lubricated completely throughout the bearing and have no fiberglass or metallic shell. The ability to make a material that has no abrasive fillers or reinforcements allows CIP to provide a product that will not damage the shaft material, and risk equipment failure due to abrasive contact surfaces.

High Load / Slow Rotating Capacity

Ideal for high load, slow speed applications.

Composite Material are Made in the USA

Manufactured in Eugene, Oregon, centrally located for timely air and/or sea shipments. CIP uses domestically sourced materials for the production of its composite materials.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.