Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand:HONYFLUO

Min. Order:1 Kilogram

Model No:HONYFLUO-PFA

Transportation:Ocean,Land,Air,Express

Packaging:Export package

Supply Ability:1000

HONYFLUO®PFA is a copolymer of tetrafluoroethylene and perfluoroalkoxyethylene. It has the same characteristics as PTFE, and as a thermoplastic resin, it also has the characteristics suitable for melt molding, and can be applied to various...

Brand:SIMONA

Min. Order:1 Kilogram

Model No:SIMONA® PVDF-EL (-GK/-SK/-CV)

Transportation:Ocean,Land,Air,Express,Others

Packaging:Export package

Supply Ability:100

Simona PVDF Sheets & Rods: Partially Fluorinated High-Performance Plastic Sheet Extruded from Kynar® resin, SIMONA® PVDF sheet and rod products provide solutions for highly demanding applications in the chemical processing industry that...

USD 5.7 ~ USD 5.9

Brand:HONYFLUO

Model No:HONYFLUO-PFA

Transportation:Ocean,Land,Air,Express

Packaging:Export package

Supply Ability:100000

HONYFLUO®PFA ROD PFA BAR PFA plastic is a small amount of perfluoropropyl perfluoroethyene ether and polytetrafluoroethyene copolymer.Melt cohesiveness is enhanced,melt viscosity is decreased,and the properties and PTFE compared with no change.PFA...

USD 5.7 ~ USD 5.9

Brand:SIMONA

Model No:SIMONA

Transportation:Ocean,Land,Air,Express,Others

Packaging:Export package

Supply Ability:Enough

Productivity:Enough

SIMONA®PVDF board (white/dark gray): Chinese polyvinylidene fluoride board, the English name Polyvinylidene fluoride, is extruded into a board with PVDF resin at high temperature. It is a fairly pure polymer. It does not contain ultraviolet...

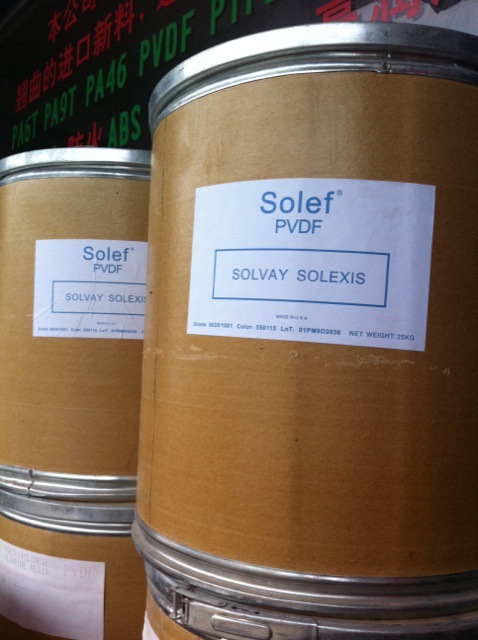

HONYFLUO®PVDF, Polyvinylidene fluoride, is a versatile fluoropolymer which is both strong and tough as reflected by its tensile properties and impact strengths. PVDF has excellent resistances to creep and fatigue. In thin sections, such as films, filament, and tubing, PVDF components are flexible and transparent. PVDF resin is produced by the Arkema and Soltex companies and sold under their respective tradenames of Kynar and Solef.

Where load bearing is important, PVDF fluoropolymers are rigid and resistant to creep under mechanical stress and load. Because PVDF is stable to sunlight, and other sources of ultraviolet radiation, it is widely used as base resins for long-lasting exterior coatings. An additional advantage over other fluoroplastics is that PVDF can be welded into tanks for acid and corrosive chemical processing in elevated temperature environments.

Special Properties of PVDF polyvinylidene fluoride

1. Its Anti degeneration is also one of the optimal fluoride resins.

9. PVDF has a good chemical stability. It will not be corrupted by acid, alkali, strong oxidizing agent and halogen at room temperature; it will not be affect by ordinary organic solvents; it can only be swelling or partly dissolved by a handful of chemicals such as fuming sulfuric acid, alkali, ketones and ether; it can be dissolved into a colloidal solution by strong polar organic solvents such as dimethyI acetamide and Dimethyl Sulfoxide (DMSO).

PVDF Sheet,PVDF Rod Regular size

PVDF KYNAR SOLID ROD Application:

Mainly in the petrochemical industry

pipe fittings

Impellers

Sleeves

Screws/nuts

Gears

Wafer carrier

Connectors/coupling pipes

PVDF Material Properties Data Sheet

℃ ℃ ℃

Mechanical Property ASTM Method Unit Kynar 1000 HD Hylar MP-102 Melt Flow Rate ISO 1133 g/10 min 1.5-2.5 7-10 Specific Gravity D-792

1.78 1.78 Water Absorption , 24hr D-570 % 0.03 0.02 Tensile Strength , 23 ℃ D-638, ISO R-527 psi 7105 7395-8250 Elongation , 23 ℃

D-638, ISO R-527 % 250 50-250 Compressive Strength , 23℃ at 5% strain D-695 psi -- -- Impact Strength , 23℃,Notched Izod D-256 J/m 160 100-200 Flexural Modulus , 23℃

D-790,ISO 178 psi 130x10-3 130x10-3 Duromater Hardness , 23℃

ISO 868 D 80 76-80 Coefficient of Friction D-1894

-- 0.3 Deformation Under Load, 23℃,1000 psi, 24 hr D-621 % -- -- Thermal Property

Melting Point ISO R-527 169 165-168 Deflection Temperature(261 psi) TMA 114-118 -- Oxygen Index D-2863 % 43 43 Max. Service Temperature

149 150 Thermal Conductivity

W/m-K 0.17-0.19 0.19-0.22 Flammability UL 94

V-O V-O Electrical Property

Surface Resistivity D-257 ohm-sq -- -- Volume Resistivity D-257 ohm-cm 1.5X10-14 1.1-10-15 Dielectric Strength (10 mil) (3.2mm for MP-10) D-149 V/mil 1600 325 Dielectric Constant,21℃,103 Hz, 60 Hz for MP-10 D-150

8.15-10.46 6.9 Dissipation Factor , 21℃,60Hz D-150

-- 0.035 Arc Resistance D-495 sec 50-60 50-60

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.