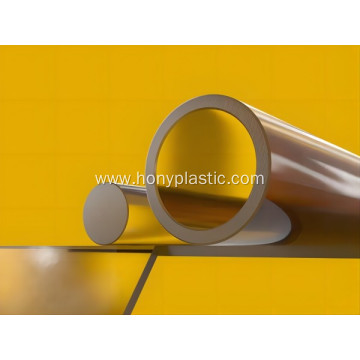

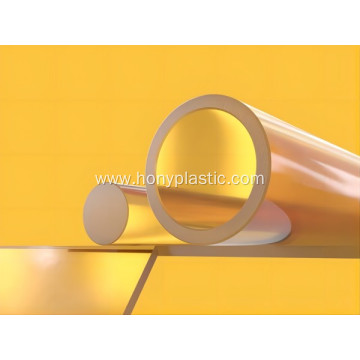

HONYPLAS®Polysulfone (PSU) is a rigid, high-strength, semi-tough, transparent plastic, with high temperature resistance and hydrolytic stability better than polycarbonate. It maintains good mechanical properties under steaming and other disinfection environments.PSU (polysulfone) is a slightly amber amorphous transparent or translucent polymer with good radiation stability, low ionic impurities and good chemical and hydrolysis resistance.

HONYPLAS®Polysulfone (PSU) characteristic:

Extremely high strength and stiffness, excellent dimensional stability, excellent chemical resistance, hydrolysis resistance, high thermal deformation resistance, not limited by weather conditions. Inherently flame retardant with low smoke generation and physical inertness (suitable for food contact). Good electrical insulation properties. Applications: tableware/catering, medical equipment, telecommunications, molded interconnects (MIDs), automotive lighting, aircraft interiors, HVAC/fluid handling.

HONYPLAS®Polysulfone (PSU) Application:

Electronic insulating parts are widely used in food processing equipment, such as machinery, pump valves, filters, heat exchangers, etc., and are also often used in medical equipment related to repeated cleaning and disinfection.

HONYPLAS® polysulfone (PSU) performs well in many fluid handling applications and has successfully replaced brass in pressurized hot water environments. Creep is low under high temperature continuous load conditions, and it can withstand continuous contact with chlorinated hot water.

HONYPLAS®Polysulfone (PSU) Features

High strength and rigidity

High impact strength (the same at lower temperatures)

Excellent dimensional stability

Good chemical resistance

Strong resistance to β, γ, X and infrared radiation

High microwave permeability

Self-extinguishing

Good antibacterial

Medium stress crack resistance

Poor weather resistance

HONYPLAS®Polysulfone (PSU) Application

Microwave oven parts

Hair dryer

Humidifier

Food industry

Pump wheel

Insulator

Medical industry