Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand:Robalon® S

Min. Order:1 Kilogram

Model No:Robalon® S PE PE-UHMW - PE 1000

Transportation:Ocean,Land,Air,Express,Others

Packaging:Export package

Supply Ability:1000

ROBALON-S by Röchling Leripa Papertech is a crosslinked, ultra-high molecular weight polyethylene (UHMWPE) grade, alloyed with molybdenum disulphide. It is free from splits or breaks. Exhibits outstanding sliding characteristics, very low friction,...

Brand:HONY

Min. Order:1 Kilogram

Model No:HONY-UHMW

Transportation:Ocean,Land,Air,Express

Packaging:Export carton pallet

Supply Ability:Enough

Productivity:50000 pcs per day

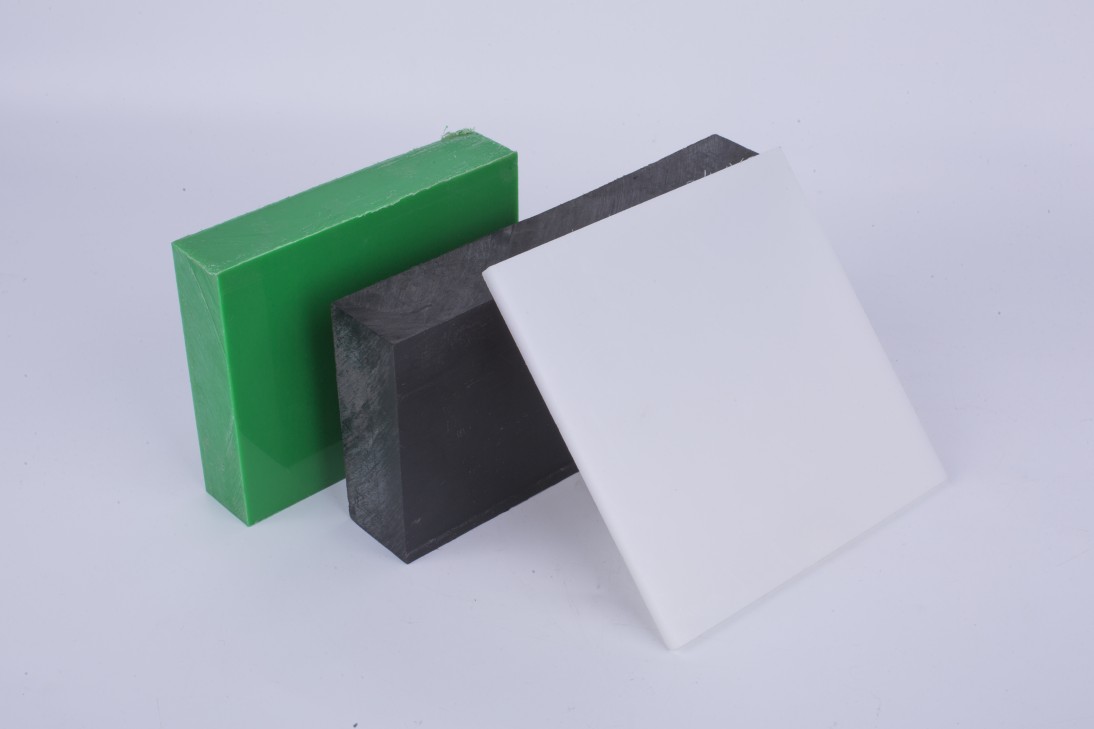

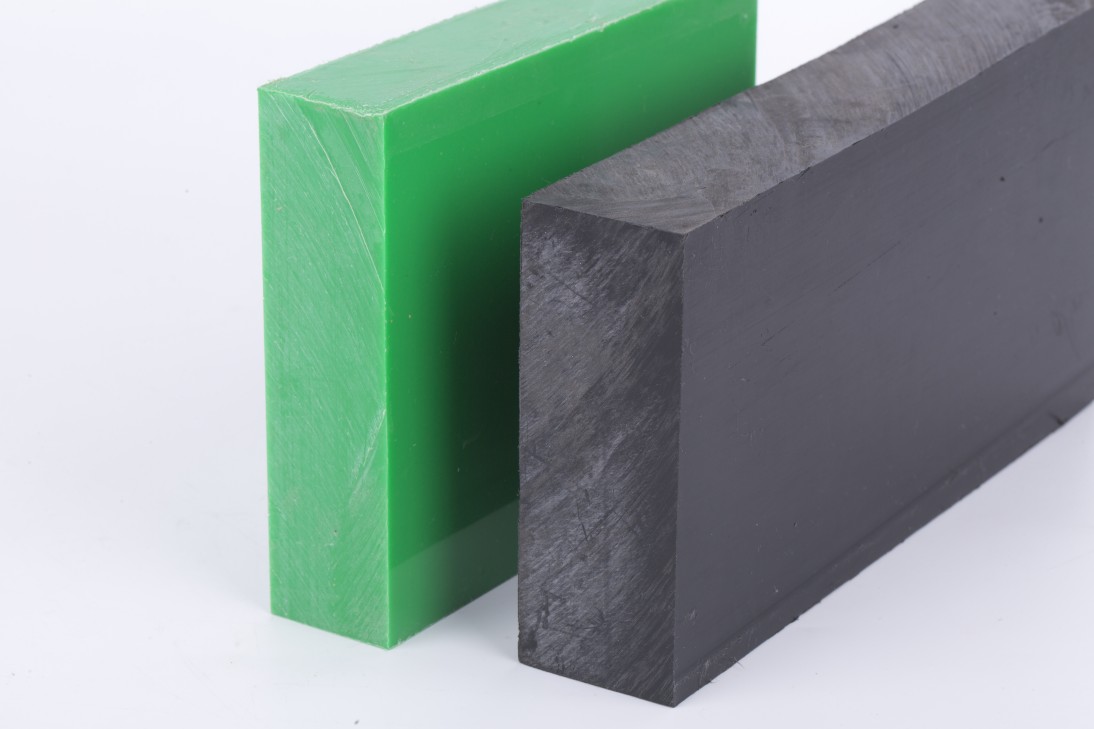

HONY®Wear Resistant UHMWPE 1000 Plastic Sheet is excellent in wear resistance, impact resistance, chemical corrosion resistance, self-lubrication, very low moisture absorption and non-toxicity. Because of its abrasion resistance, chemical resistance...

HONY®Polyethylene (PE) plastic is a semi-crystalline thermoplastic with high toughness and excellent chemical resistance. Compared with other plastics, polyethylene plastics have lower mechanical strength and high temperature resistance.High Density Polyethylene (HDPE) sheet is extremely strong against impact, abrasion resistant, and exhibits a low coefficient of friction. The material is also moisture, stain, and odor resistant, and is FDA approved for use in the food processing industry (mainly for cutting boards). The material's durability makes it a perfect match for a variety of applications such as water tanks, chute linings, bottle/bottle cap production and numerous other industrial uses. Borated HDPE offers radiation protection in nuclear facility applications.

High-density Poly Ethylene also is known as HDPE is made from a cord of ethylene molecules (the poly part of polyethylene), and is famous for its light weight and high durability.

The preference of HDPE sheets is increasing from leaps and bounds in the market today, as it's able to cut down on the material which is then used for producing and packaging products for its strength and weight.

It is also available at tap plastics in sheet form with either a smooth or textured surface. The textured surface is also called cutting board. Both smooth and textured surfaces are FDA approved for food contact.

HONY®PE series products include the following materials:

Polyethylene (PE) Polyethylenes are semi-crystalline materials with excellent chemical resistance, good fatigue and wear resistance and a wide range of properties. Polyethylenes are easy to distinguish from other plastics because they float in water. Polyethylenes provide good resistance to organic solvents, degreasing agents and electrolytic attack. Polyethylene is used more than any other thermoplastic polymer. There are a wide variety of grades and formulations available that have an equally wide range of properties.

Benefits

Durability Easily fabricated

Chemical resistance Abrasion resistance

Good electrical properties

Impact resistance

Low coefficient of friction

Moisture resistance

Applications

Packaging

Skid

Plates

Conveyer

Systems

Tanks

Containers

Truck liners

POLYETHYLENE GRADES Low Density Polyethylene (LDPE) This extruded material offers good corrosion resistance and low moisture permeability. It can be used in applications where corrosion resistance is important, but stiffness, high temperature, and structural strength are not. A highly flexible product, LDPE is used widely in orthopaedic products, or where mobility without stress fatigue is desired. LDPE is also frequently used in consumer packaging, bags, bottles, and liners.

Benefits

Lightweight

Formable Impact

Resistant

Good electrical properties

Easily cleaned

Easily Fabricated

Applications

Chemical resistant tank and containers

Food storage containers

Laboratory equipment

Corrosion resistant work surfaces

Vacuum formed end caps and tops

Moisture barrier

POLYETHYLENE GRADES High Density Polyethylene (HDPE) Representing the largest portion of the polyethylene applications, HDPE offers excellent impact resistance, light weight, low moisture absorption, and high tensile strength. HDPE is also non-toxic and non-staining and meets FDA and USDA certification for food processing.

Benefits

Abrasion Resistant

High impact resistance

Low coefficient of friction

Abrasion resistant

Scratch and marking resistant

Chemical resistant

Water and moisture resistant

Applications

Food cutting boards

Corrosion resistant covers

Pipe flanges

Radiation shielding

Self-supporting containers

Prosthetic devices

Ultra High Molecular Weight Polyethylene (UHMW PE) UHMWPE is light weight (1/8 the weight of steel), high tensile strength, and is easily machined. It is the ideal material for many wear parts in machinery and equipment as well as a superb lining in material handling systems and storage containers. UHMW PE is self-lubricating, shatter resistant, long-wearing, abrasion and corrosion resistant. It meets FDA and USDA acceptance for food and pharmaceutical equipment and is a good performer in applications up to 180 °F (82 °C) or when periodically cleaned with live steam or boiling water to sterilize.

uhmwpe Benefits

Durability

Easily fabricated

Chemical resistance

Abrasion resistance

Electrical properties

Impact resistance

Low coefficient of friction

Moisture resistance

hdpe Applications

Tanks and containers

Food storage containers

Laboratory equipment

Disposable formed products

Surface structures

Vacuum formed end caps and tops

Moisture barrier

Sheet Hdpe Feature

Low density

Excellent wear resistance

Very resistant to damage

High toughness (the same at low temperature)

High elongation at break

Excellent electrical and dielectric properties

Very low water absorption

Low vapor permeability

Strong chemical resistance

Good resistance to stress cracking

Food safety

Polyethylene Sheet Application

Guide pulley

Guide chain

Pads for storage blocks, silos and conveyor channels

Suction cups and filter plates

Pumps and valves

Gasket

Slide model

Food industry parts

Item RESULT UNIT PARAMETER NORM USED Mechanical properties Modulus of elasticity 1000 MPa In tension DIN EN ISO 527-2 Modulus of elasticity 1000 - 1400 MPa In flexure DIN EN ISO 527-2 Tensile strength at yield 25 MPa 50 mm/min DIN EN ISO 527-2 Impact strength (Charpy) 140 Kj/m 2 Max. 7,5j Notched Impact stren. (Charpy) No break Kj/m 2 Max. 7,5j Ball indentation hardness 50 MPa ISO 2039-1 Creep rupture strength 12,50 MPa After 1000 hours static load 1% elong. after 1000 hours Against steel p=0,05 N/mm 2 Time yield limit 3 MPa Coefficient of friction 0,29 ------ Thermal properties Glass transition temperature -95 °C DIN 53765 Crystalline melting point 130 °C DIN 53765 Service temperature 90 °C Short term Service temperature 80 °C Long term Thermal expansion 13 - 15 10-5K-1 DIN 53483 Specific heat 1,70 - 2,00 J/(g+K) ISO 22007-4:2008 Thermal conductivity 0,35 - 0,43 W/(K+m) ISO 22007-4:2008 Heat distorsion temperature 42 - 49 °C Method A R75 Heat distorsion temperature 70 - 85 °C Method B R75

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.