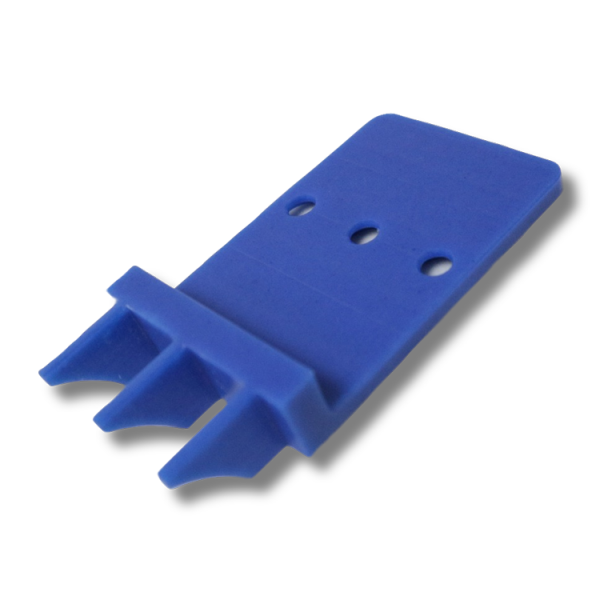

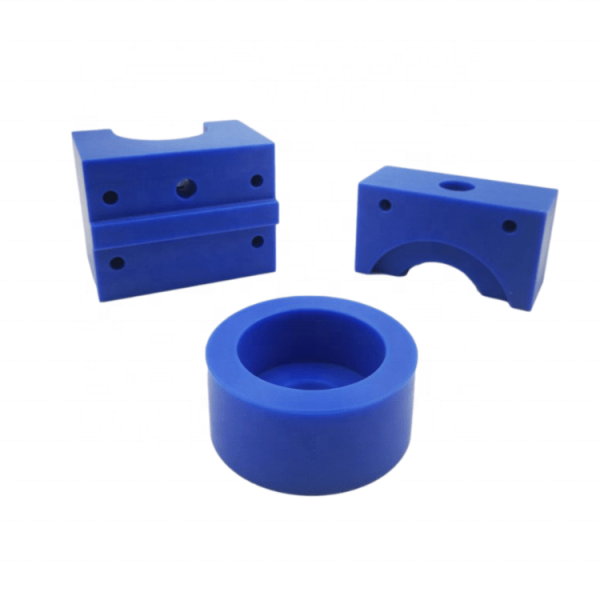

MC Nylon (PA) CNC Machining

Get Latest Price| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,DDP |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Shanghai |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,DDP |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Shanghai |

Model No.: HONY-NYLON

Brand: HONY

| Selling Units | : | Piece/Pieces |

| Package Type | : | Export package |

The file is encrypted. Please fill in the following information to continue accessing it

Nylon is a versatile and widely used material in CNC machining due to its exceptional properties. Its high tensile strength, low coefficient of friction, and resistance to wear and abrasion make it an excellent choice for applications requiring durability and reliability, such as gears, bushings, and bearings. Additionally, nylon's low moisture absorption and good dimensional stability ensure consistent performance even in humid or varying temperature conditions.

Its ease of machining, coupled with its chemical resistance, also makes it suitable for applications in the automotive, aerospace, and medical industries. With its remarkable combination of properties, nylon stands out as a versatile and reliable material for a diverse range of CNC machining applications.

Lathe processing nylon method

1. Prepare tools and raw materials: lathe, nylon bar material, cutting fluid, tool (lathe or cutting tool)

2. Adjust the speed and cutting depth of lathe: according to the hardness and other characteristics of nylon, adjust the speed and cutting depth of lathe to get the best machining effect. 3. Fix the nylon material: use special fixture to fix the nylon material.

3. fix the nylon material: use the special fixture to fix the nylon material on the lathe and ensure its stability and balance.

4. Apply Cutting Fluid: Apply cutting fluid between the nylon material and the tool to minimize friction and heat during machining.

5. Begin machining: Use a turning or cutting tool to progressively machine the nylon material to the desired shape and size, taking care to keep the tool sharp and to clean it regularly of swarf.

6. Finish: At the end of the process, clean and inspect the processed nylon to ensure that it meets specifications and quality requirements.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.