NYLATRON® MC 901 CNC part

Get Latest Price| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,HongKong |

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,HongKong |

Model No.: Nylatron®MC 901

Brand: Nylatron®MC 901

| Selling Units | : | Piece/Pieces |

| Package Type | : | Export carton pallet |

The file is encrypted. Please fill in the following information to continue accessing it

NYLATRON®MC901 custom spur gear Blue Nylon MC901 Material Spur Gear Without Hub Module:M0.5-M10 Material: C45/Stainless steel/Brass/Plastic/POM/Nylon Pressure angle:20 degree Precision grade:DIN6/DIN7/DIN8/DIN9/DIN10 Machining process:Hobbing, Milling, Drilling, Shaving, Grinding Heat treatment:Hardening and Tempering, High Frequency Quenching,Carburizing etc . Surface treatment:Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating

Our advantage

Plastic gears material:Nylon;POM;UHMWPE

We manufacture plastic parts according to customers' designs;

We can offer material certification,test report and relate surface-treatment report;

Platic gears process:CNC machining,Milling,Drilling,Turning;

Products shown on the website are OEM;

Customized designs are welcome;

Plastic gears OEM/ODM orders are welcome;

Our Service

1)We are a manufacturer integrating industry and trade.

2)We foceus on processing plastic products for 13 years.

3)We are located in guangzhou huangpu,near guangzhou wuchong port.

4)Flexible delivery,Super quality,Factory price.

5)OEM Service: customize color,size,material.

6)MOQ:1pc.

Processing equipment:

CNC machinery center,engraving machine,Cnc lathe and other equipment processing services.

Processing materials:

PTFE,POM,Nylon,UHMWPE,PEEK,HDPE,PU,PTE.ect(only plastic material)

Commitment:

if the parts cannot be used because of the processing problems,we will be responsible for free repair or reprocessing,and bear the

round-trip freight.

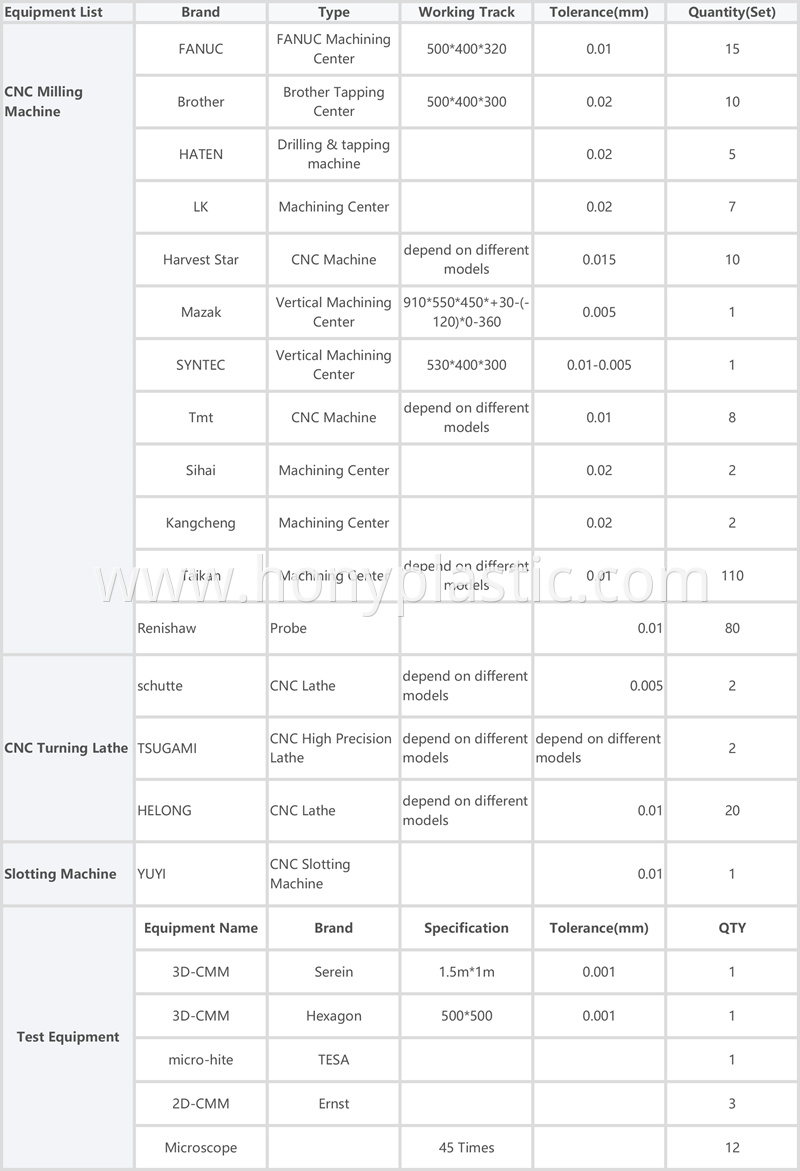

Our machine list

CNC Machined processing

Technological process:

Step.01: Raw material preparation

Step.02: Audit and design drawings

Step.03: Processing products

Step.04: Quality inspection

Step.05: Repair product burr and inventory

Step.06: Packing

Service process:

Step.01: The format of the drawing can be identified

Step.02: Response quotation and delivery time.

Step.03: Confirm the information and pay the order.

Step.04: Complete the order and wait for delivey.

Drawing format:

2D:JPG, PDF, DWG, DXF, EXB

3D:SLDPRT,PRT, CATPART STP, STEP, IGS, X_T

CNC Service

Our machine

Our partner

Package

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.