What are the outstanding features of PI parts machining?

PI parts machining manufacturers must have the road to take you to understand: widely used in the field of aerospace and aviation PI parts in the end what are the advantages? Before introducing the advantages of PI parts processing, first of all to understand what is PI. PI is the abbreviation of polyimide. Is the main chain containing acyl imino group (-C (O) -N -C (O) -) polymer.

PI is a large molecule containing acylimino polymer on the main chain, belongs to the aromatic compounds, is formed by the condensation of dianhydride and diamine, PI molecule contains a large number of benzene rings on the main chain, as well as the acylimide group is incorporated into the benzene ring and the formation of five-membered heterocyclic ring, the molecular chain of the rigidity of the big, the intermolecular force is strong, the convergence of the density of the high, so that the PI has a series of excellent performance. PI due to its composition of dianhydride and diamine structure is not the same, the performance also varies.

PI polyimide, because of its outstanding characteristics in performance and synthesis, whether as a structural material or as a functional material, its great application prospects have been fully recognized. PI polyimide has been fully recognized as a It has been fully recognized as a “problem solver” (protion solver), and it is believed that “without polyimide, there would be no microelectronics technology today”.

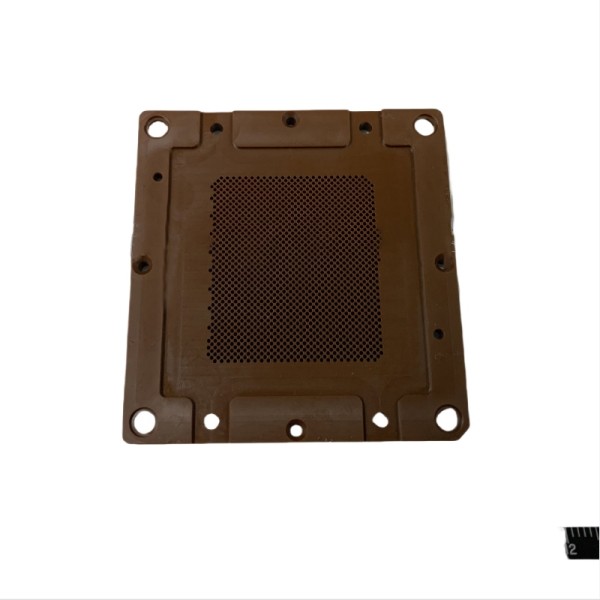

PI parts processing has excellent heat resistance, is a major heat-resistant plastics, can make high-temperature bearings, pistons, piston rings, connecting rods, gears, etc.; PI and PPS (polyphenylene sulfide squ squinting) blending, the resulting material has good mechanical strength, heat resistance, corrosion resistance and resistance to stress cracking Para-equivalent level; PI parts processing in the field of aerospace has shown an incomparable superiority; for example, it can be used in place of bronze, aluminum alloys and other materials to make PI parts processing engine. For example, it can replace bronze, aluminum alloy and other materials to make certain parts on the engine of PI parts processing, and its performance far exceeds that of metal materials. PI parts can be used to make protective sealing devices for spaceships, as well as spacesuits, sunshade systems, emergency oxygen supply systems, etc. PI parts can also be used to make valves and other parts for space shuttles.

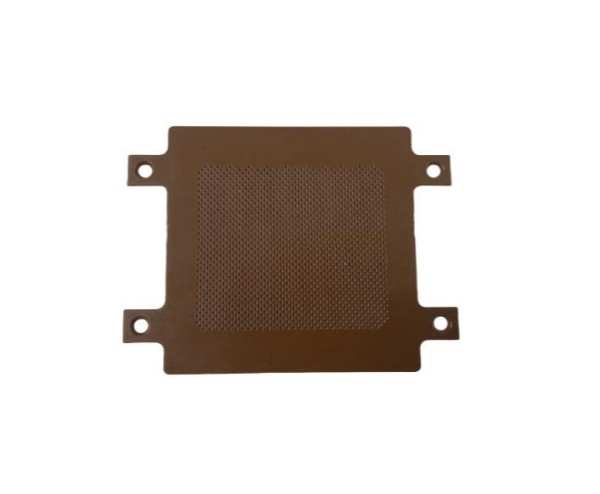

Precautions for processing PAI parts

The thermal expansion rate of plastic is more than 10 times that of metal;

Plastic is slower than metal to dissipate heat, to avoid localized overheating;

The softening (melting) temperature of plastic is much lower than that of metal;

PAI parts processing plastic is more elastic than metal

In view of these differences between plastic and metal, you will be in practice to master the fixture, tool material, angle, speed and feed rate to achieve the best machining results. It is recommended to use front facing tools with ground chamfers on all sides. For longer tool life and optimum surface finish, carbide tools with ground surfaces are recommended.